Process check on welding

Title

Process check on welding

Description

Instructions for welding on one side. On reverse accepting quote for an order.

Date

1945-02-26

1945-01-10

Coverage

Language

Format

One side handwritten, reverse side typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10037

Transcription

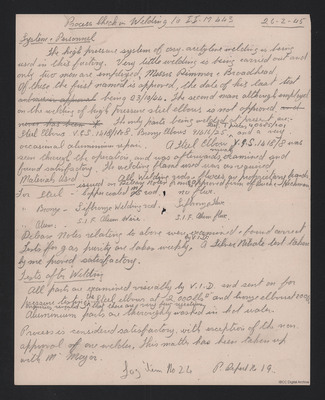

[underlined] Process Check on Welding to I.I.M 443 [/underlined] [underlined] 26-2-45 [/underlined]

[Underlined] System & Personnel [/underlined]

The high pressure system of oxy-acetylene welding is being used in this factory. Very little welding is being carried out and only two men are employed, Messrs Rimmer & Broadhead.

Of these the first named is approved, the date of his last test [deleted] submission approval [/deleted] being 23/10/44. The second man although employed on the welding of high pressure steel elbows is not approved. [deleted] and never has been [symbol] [/deleted] The only parts being welded at present are:- Steel Elbows V.G.S. 1418/1108. Bronze Elbows 91616/25 [inserted] Steel. T pieces 40685/201 [/inserted] and a very occasional aluminium repair. A Steel Elbow V.G.S. 1418/8 was seen through the operation, and was afterwards [inserted] visually [/inserted] examined and found satisfactory. The welding flame used was as required.

[underlined] Materials Used [/underlined] All welding rods & fluxes are proprietary brands.

issued on Release Notes from the approved firm of Buche Hickman.

For Steel – Copper coated [deleted]ms [/deleted] [inserted]m [/inserted] rod no flux.

For Bronze – Sifbronze Welding rod. Sifbronze Flux.

For Alum. – S.I.F. Alum Wire. S.I.F. Alum flux.

Release Notes relating to above were examined & found correct. Tests for gas purity are taken weekly [inserted] by V.I D: [/inserted] a Silver Nitrate test taken by me proved satisfactory.

[underlined] Tests after Welding [/underlined]

All parts are examined visually by V.I.D. and sent on for pressure testing [inserted] the [/inserted] Steel Elbows at 2,000lbs [symbol]” and bronze elbows at 200lbs

Enquiries revealed that there are very few rejections.

Aluminium parts are thoroughly washed in hot water.

Process is considered satisfactory, with exception of the non-approval of one welder. This matter has been taken up with M Major.

Log Item No 24 P. [indecipherable word] No 19.

[Page Break]

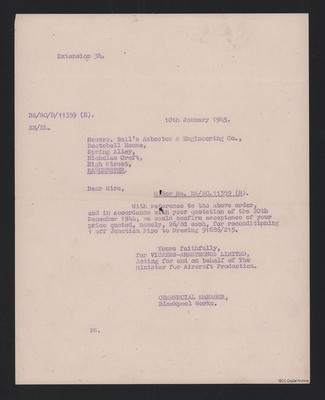

Extension 34.

BS/SG/D/11359 (R).

EB/EL.

10th January 1945.

Messrs. Bell’s Asbestos & Engineering Co.,

Bestobell House,

Spring Alley,

Nicholas Croft,

High Street,

[underlined] MANCHESTER [/underlined].

Dear Sirs,

[underlined] Order No. BS/SC.11359 (R). [/underlined]

With reference to the above order, and in accordance with your quotation of the 20th December 1944, we would confirm acceptance of your price quoted, namely 26/8d each, for reconditioning 1 off Junction Pipe to Drawing 91686/215.

Yours faithfully,

for VICKERS-AMRSTRONG LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

[Underlined] System & Personnel [/underlined]

The high pressure system of oxy-acetylene welding is being used in this factory. Very little welding is being carried out and only two men are employed, Messrs Rimmer & Broadhead.

Of these the first named is approved, the date of his last test [deleted] submission approval [/deleted] being 23/10/44. The second man although employed on the welding of high pressure steel elbows is not approved. [deleted] and never has been [symbol] [/deleted] The only parts being welded at present are:- Steel Elbows V.G.S. 1418/1108. Bronze Elbows 91616/25 [inserted] Steel. T pieces 40685/201 [/inserted] and a very occasional aluminium repair. A Steel Elbow V.G.S. 1418/8 was seen through the operation, and was afterwards [inserted] visually [/inserted] examined and found satisfactory. The welding flame used was as required.

[underlined] Materials Used [/underlined] All welding rods & fluxes are proprietary brands.

issued on Release Notes from the approved firm of Buche Hickman.

For Steel – Copper coated [deleted]ms [/deleted] [inserted]m [/inserted] rod no flux.

For Bronze – Sifbronze Welding rod. Sifbronze Flux.

For Alum. – S.I.F. Alum Wire. S.I.F. Alum flux.

Release Notes relating to above were examined & found correct. Tests for gas purity are taken weekly [inserted] by V.I D: [/inserted] a Silver Nitrate test taken by me proved satisfactory.

[underlined] Tests after Welding [/underlined]

All parts are examined visually by V.I.D. and sent on for pressure testing [inserted] the [/inserted] Steel Elbows at 2,000lbs [symbol]” and bronze elbows at 200lbs

Enquiries revealed that there are very few rejections.

Aluminium parts are thoroughly washed in hot water.

Process is considered satisfactory, with exception of the non-approval of one welder. This matter has been taken up with M Major.

Log Item No 24 P. [indecipherable word] No 19.

[Page Break]

Extension 34.

BS/SG/D/11359 (R).

EB/EL.

10th January 1945.

Messrs. Bell’s Asbestos & Engineering Co.,

Bestobell House,

Spring Alley,

Nicholas Croft,

High Street,

[underlined] MANCHESTER [/underlined].

Dear Sirs,

[underlined] Order No. BS/SC.11359 (R). [/underlined]

With reference to the above order, and in accordance with your quotation of the 20th December 1944, we would confirm acceptance of your price quoted, namely 26/8d each, for reconditioning 1 off Junction Pipe to Drawing 91686/215.

Yours faithfully,

for VICKERS-AMRSTRONG LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

Collection

Citation

“Process check on welding,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28960.

Item Relations

This item has no relations.