Degreasing to IIM,422

Title

Degreasing to IIM,422

Description

Covers degreasing operations in factory. On the reverse a letter accepting price quoted.

Date

1945-01-10

1945-03-18

Coverage

Language

Format

One side handwritten, reverse typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10038

Transcription

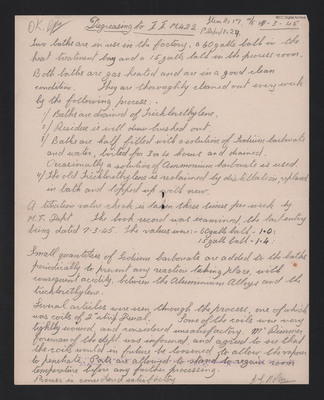

[inserted] OK [indecipherable letters] [/inserted] [underlined] Degreasing to I.I. M.422 [/underlined]

[indecipherable word] No 17. P. Depot No 24. W/E [underlined] 18-3-45 [/underlined]

Two baths are in use in the factory, a 60 galls bath in the heat treatment bay and a 15 galls bath in the process room.

Both baths are gas heated and are in a good clean condition. They are thoroughly cleaned out every week by the following process:-

1/ Baths are drained of Trichlorethylene,

2/ Residue is well [deleted] drai [/deleted] brushed out,

3/ Baths are half filled with a solution of Sodium Carbonate and water, boiled for 3 or 4 hours and drained. Occasionally a solution of Ammonium Carbonate is used.

4/ The old Trichlorethylene is reclaimed by distillation, replaced in bath and topped up with new.

A titration value check is taken three times per week by M.T. Dept. The book record was examined, the last entry being dated 7-3-45. The values were:- 60 galls bath – 1.0: 15 galls bath – 1.4:

Small quantities of Sodium Carbonate are added to the baths periodically to prevent any reaction taking place, with consequent acidity, between the Aluminium Alloys and the trichlorethylene.

Several articles were seen through the process, one of which was coils of 2” strip Dural. Some of the coils were very tightly wound and considered unsatisfactory. Mr Dimmer foreman of the dept. was informed, and agreed to see that the coils would in future be loosened to allow the vapour to penetrate. Parts are allowed to stand to regain room temperature before any further processing.

Process is considered satisfactory.

J.F. Nolan

[page break]

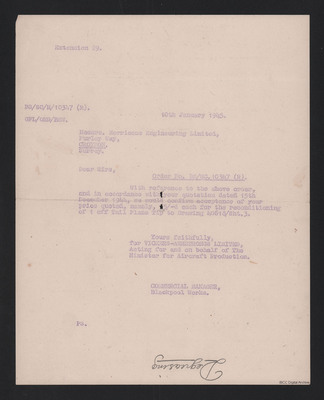

Extension 29.

BS/SC/M/10347 (R).

10th January 1945.

GFL/ORD/BEW.

Messrs. Morrisons Engineering Limited,

Purley Way,

[underlined] CROYDON. [/underlined]

Surrey.

Dear Sirs,

[underlined] Order No. BS/SC. 10347 (R). [/underlined]

With reference to the above order, and in accordance with your quotation dated 15th December 1944, we would confirm acceptance of your price quoted, namely, [missing number] 5/-d each for the reconditioning of 1 off Tail Plane Tip to Drawing 40618/Sht.3.

Yours faithfully,

for VICKERS-ARMSTRONG LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

[inverted][underlined] Degreasing [/underlined][/inverted]

[indecipherable word] No 17. P. Depot No 24. W/E [underlined] 18-3-45 [/underlined]

Two baths are in use in the factory, a 60 galls bath in the heat treatment bay and a 15 galls bath in the process room.

Both baths are gas heated and are in a good clean condition. They are thoroughly cleaned out every week by the following process:-

1/ Baths are drained of Trichlorethylene,

2/ Residue is well [deleted] drai [/deleted] brushed out,

3/ Baths are half filled with a solution of Sodium Carbonate and water, boiled for 3 or 4 hours and drained. Occasionally a solution of Ammonium Carbonate is used.

4/ The old Trichlorethylene is reclaimed by distillation, replaced in bath and topped up with new.

A titration value check is taken three times per week by M.T. Dept. The book record was examined, the last entry being dated 7-3-45. The values were:- 60 galls bath – 1.0: 15 galls bath – 1.4:

Small quantities of Sodium Carbonate are added to the baths periodically to prevent any reaction taking place, with consequent acidity, between the Aluminium Alloys and the trichlorethylene.

Several articles were seen through the process, one of which was coils of 2” strip Dural. Some of the coils were very tightly wound and considered unsatisfactory. Mr Dimmer foreman of the dept. was informed, and agreed to see that the coils would in future be loosened to allow the vapour to penetrate. Parts are allowed to stand to regain room temperature before any further processing.

Process is considered satisfactory.

J.F. Nolan

[page break]

Extension 29.

BS/SC/M/10347 (R).

10th January 1945.

GFL/ORD/BEW.

Messrs. Morrisons Engineering Limited,

Purley Way,

[underlined] CROYDON. [/underlined]

Surrey.

Dear Sirs,

[underlined] Order No. BS/SC. 10347 (R). [/underlined]

With reference to the above order, and in accordance with your quotation dated 15th December 1944, we would confirm acceptance of your price quoted, namely, [missing number] 5/-d each for the reconditioning of 1 off Tail Plane Tip to Drawing 40618/Sht.3.

Yours faithfully,

for VICKERS-ARMSTRONG LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

[inverted][underlined] Degreasing [/underlined][/inverted]

Collection

Citation

“Degreasing to IIM,422,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28961.

Item Relations

This item has no relations.