Anodic oxidation

Title

Anodic oxidation

Description

Covers baths, treatment of parts, tests and records. On the reverse letter requesting supply of materials.

Creator

Date

1945-05-23

1945-05-15

Coverage

Language

Format

One side handwritten, reverse typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10041

Transcription

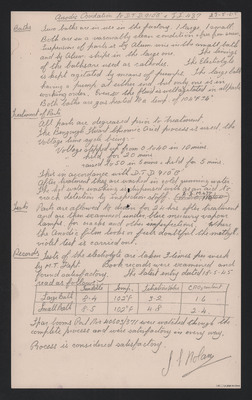

[underlined] Anodic Oxidation to D.T.D.910”B” & I.I.437 [/underlined] [underlined] 23-5-45 [/underlined]

[underlined] Baths [/underlined]

Two baths are in use in the factory. 1 large, 1 small: Both are in a reasonably clean condition & free from scum. Suspension of parts is by Alum: wire in the small bath and by Alum: strips in the large one. The linings of the baths are used a cathodes. The Electrolyte is kept agitated by means of pumps. The large bath having a pump at either end, but only one is in working order. Even so the fluid is well agitated in all parts. Both baths are gas heated to a temp: of 104°F. [symbol] 4°.

[underlined] Treatment of Parts [/underlined]

All parts are degreased prior to treatment. The Bengough Stuart Chromic Acid process is used, the voltage time cycle being:-

Voltage stepped up from 0 to 40 in 10 mins.

Voltage held for 20 mins.

Voltage raised to 50 in 5 mins & held for 5 mins.

This in accordance with D.T.D.910”B”

After treatment they are washed in cold running water. The hot water washing is dispensed with as an aid to crack detection by inspection staff. ([deleted] W.S.O.110/42 [/deleted][inserted]I.I.M.437 [/inserted])

[underlined] Tests [/underlined]

Parts are allowed to drain for 24hrs after treatment and are then examined under, blue mercury vapour lamps, for cracks and other imperfections. Where the Anodic film looks or feels doubtful the methyl violet test is carried out.

[underlined]Records [/underlined]

Tests of the electrlyte are taken 3 times per week by M.T. Dept. Book records were examined and found satisfactory. The latest entry dated 18-5-45 read as follows:-

Twaddle Temp. Titialtion Value CRO3 content

Large Bath 8.4 102° 3.2 1.6

Small Bath 8.5 102° 4.8 2.4

Spar booms Part Nos 40603/371 were watched through the complete process and were satisfactory in every way.

Process is considered satisfactory.

J.F. Nolan

[Page Break]

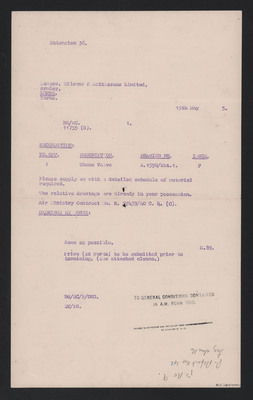

Extension 36.

Messrs. Wilson & Mathieson Limited,

Armley,

[underlined] LEEDS [/underlined].

Yorks.

15th May 5.

BS/SC. 1.

11755 (R).

[underlined] RECONDITION: [/underlined]

[underlined] NO. OFF [/underlined]. [underlined] DESCRIPTION [/underlined]. [underlined] DRAWING NO[/underlined]. [underlined] ISSUE [/underlined].

1 Choke Valve A.1590/Sht.1. F

Please supply us with a detailed schedule of material required.

The relative drawings are already in your possession.

Air Ministry Contract No. B. 92439/40 C. 4. (C).

[underlined] CARRIAGE EX WORKS: [/underlined]

Soon as possible.

Price (ex Works) to be submitted prior to invoicing. (See attached clause.) M.89.

BS/SC/P/ORD.

EY/PS.

[Stamp]

TO GENERAL CONDITIONS CONTAINED IN A.M. FORM 705.

[Stamp]

SUBJECT TO INSPECTION AND RELEASE BY YOUR INSPECTING [indecipherable word] AS APPROVED BY A.I.D

[inverted][inserted] P.No.9.

P.Report No 42

Log item nos [/inserted][/inverted]

[underlined] Baths [/underlined]

Two baths are in use in the factory. 1 large, 1 small: Both are in a reasonably clean condition & free from scum. Suspension of parts is by Alum: wire in the small bath and by Alum: strips in the large one. The linings of the baths are used a cathodes. The Electrolyte is kept agitated by means of pumps. The large bath having a pump at either end, but only one is in working order. Even so the fluid is well agitated in all parts. Both baths are gas heated to a temp: of 104°F. [symbol] 4°.

[underlined] Treatment of Parts [/underlined]

All parts are degreased prior to treatment. The Bengough Stuart Chromic Acid process is used, the voltage time cycle being:-

Voltage stepped up from 0 to 40 in 10 mins.

Voltage held for 20 mins.

Voltage raised to 50 in 5 mins & held for 5 mins.

This in accordance with D.T.D.910”B”

After treatment they are washed in cold running water. The hot water washing is dispensed with as an aid to crack detection by inspection staff. ([deleted] W.S.O.110/42 [/deleted][inserted]I.I.M.437 [/inserted])

[underlined] Tests [/underlined]

Parts are allowed to drain for 24hrs after treatment and are then examined under, blue mercury vapour lamps, for cracks and other imperfections. Where the Anodic film looks or feels doubtful the methyl violet test is carried out.

[underlined]Records [/underlined]

Tests of the electrlyte are taken 3 times per week by M.T. Dept. Book records were examined and found satisfactory. The latest entry dated 18-5-45 read as follows:-

Twaddle Temp. Titialtion Value CRO3 content

Large Bath 8.4 102° 3.2 1.6

Small Bath 8.5 102° 4.8 2.4

Spar booms Part Nos 40603/371 were watched through the complete process and were satisfactory in every way.

Process is considered satisfactory.

J.F. Nolan

[Page Break]

Extension 36.

Messrs. Wilson & Mathieson Limited,

Armley,

[underlined] LEEDS [/underlined].

Yorks.

15th May 5.

BS/SC. 1.

11755 (R).

[underlined] RECONDITION: [/underlined]

[underlined] NO. OFF [/underlined]. [underlined] DESCRIPTION [/underlined]. [underlined] DRAWING NO[/underlined]. [underlined] ISSUE [/underlined].

1 Choke Valve A.1590/Sht.1. F

Please supply us with a detailed schedule of material required.

The relative drawings are already in your possession.

Air Ministry Contract No. B. 92439/40 C. 4. (C).

[underlined] CARRIAGE EX WORKS: [/underlined]

Soon as possible.

Price (ex Works) to be submitted prior to invoicing. (See attached clause.) M.89.

BS/SC/P/ORD.

EY/PS.

[Stamp]

TO GENERAL CONDITIONS CONTAINED IN A.M. FORM 705.

[Stamp]

SUBJECT TO INSPECTION AND RELEASE BY YOUR INSPECTING [indecipherable word] AS APPROVED BY A.I.D

[inverted][inserted] P.No.9.

P.Report No 42

Log item nos [/inserted][/inverted]

Collection

Citation

J F Nolan, “Anodic oxidation,” IBCC Digital Archive, accessed October 29, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28964.

Item Relations

This item has no relations.