Riveting

Title

Riveting

Description

Report of where riveting is carried out in factory and how it is conducted. Includes heat treatment control. On the reverse letter concerning an order.

Date

1945-01-10

Temporal Coverage

Coverage

Language

Format

One side handwritten, reverse side typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10040

Transcription

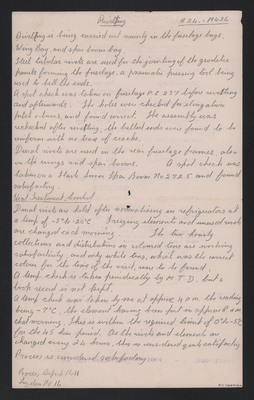

[Underlined] Rivet[deleted] t [/deleted]ing A.24. + M426 [/underlined]

Rivet[deleted] t [/deleted]ing is being carried out mainly in the fuselage bays, Wing Bay, and spar boom bay.

Steel tubular rivets are used for the jointing of the geodetic panels forming the fuselage, a pneumatic pressing tool being used to bell the ends.

A spot check was taken on fuselage P.G.237 before rive[deleted] t [/deleted]ting and afterwards. The holes were checked for elongation pitch & burrs, and found correct. The assembly was rechecked after rive[deleted] t [/deleted]ting, the belled ends were found to be uniform with no trace of cracks.

Dural rivets are used on the rear fuselage frames, also on the wings and spar booms. A spot check was taken on a Starb Inner Spar Boom No 2725 and found satisfactory.

[Underlined] Heat Treatment Control [/underlined]

Dural rivets are held after normalising in refrigerators at a temp of -5° to -20°C. Freezing elements and unused rivets are changed each morning. The two hourly collections and distributions in coloured tins are working satisfactorily, and only white tins, which was the correct colour for the time of the visit, were to be found. A temp check is taken periodically by M.T.D. but a book record is not kept.

A temp check was taken by me at approx. 4 pm. the reading being -7°C, the element having been put in approx 8.A M. that morning. This is within the required limit of 0° to -5°C for the 45 hour period. As the rivets and elements are changed every 24 hours, this is considered quite satisfactory

Process is considered satisfactory.

Process Report No 11

Log item No 16

[Page break]

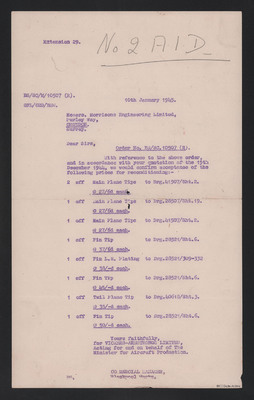

Extension 29. [Underlined] No 2 A.I.D. [/underlined]

BS/SC/M/10507 (R).

10th January 1945.

GFL/ORD/BEW.

Messrs. Morrisons Engineering Limited,

Purley Way,

[Underlined] CROYDEN [/underlined].

Surrey.

Dear Sirs,

[Underlined] Order No. BS/SC. 10507 (R) [/underlined].

With reference to the above order, and in accordance with your quotation of the 15th December 1944, we would confirm acceptance of the following prices for reconditioning:–

2 off Main Plane Tips to Drg.41507/Sht.2.

[Underlined] @ 27/6d each. [/underlined]

1 off Main Plane Tips to Drg.28507/Sht.19.

[Underlined] @ 27/6d each [/underlined].

1 off Main Plane Tips to Drg.41507/Sht.2.

[Underlined] @ 27/6d/ each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 37/6d. each [/underlined].

1 off Fin L.E. Plating to Drg.28521/309-332

[Underlined] @38/-d each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 45/-d each [/underlined].

1 off Tail Plane Tip to Drg.40618/Sht.3.

[Underlined] @ 35/-d each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 50/-d each. [/underlined]

Yours faithfully,

For VICKERS-ARMSTRONGS LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

Rivet[deleted] t [/deleted]ing is being carried out mainly in the fuselage bays, Wing Bay, and spar boom bay.

Steel tubular rivets are used for the jointing of the geodetic panels forming the fuselage, a pneumatic pressing tool being used to bell the ends.

A spot check was taken on fuselage P.G.237 before rive[deleted] t [/deleted]ting and afterwards. The holes were checked for elongation pitch & burrs, and found correct. The assembly was rechecked after rive[deleted] t [/deleted]ting, the belled ends were found to be uniform with no trace of cracks.

Dural rivets are used on the rear fuselage frames, also on the wings and spar booms. A spot check was taken on a Starb Inner Spar Boom No 2725 and found satisfactory.

[Underlined] Heat Treatment Control [/underlined]

Dural rivets are held after normalising in refrigerators at a temp of -5° to -20°C. Freezing elements and unused rivets are changed each morning. The two hourly collections and distributions in coloured tins are working satisfactorily, and only white tins, which was the correct colour for the time of the visit, were to be found. A temp check is taken periodically by M.T.D. but a book record is not kept.

A temp check was taken by me at approx. 4 pm. the reading being -7°C, the element having been put in approx 8.A M. that morning. This is within the required limit of 0° to -5°C for the 45 hour period. As the rivets and elements are changed every 24 hours, this is considered quite satisfactory

Process is considered satisfactory.

Process Report No 11

Log item No 16

[Page break]

Extension 29. [Underlined] No 2 A.I.D. [/underlined]

BS/SC/M/10507 (R).

10th January 1945.

GFL/ORD/BEW.

Messrs. Morrisons Engineering Limited,

Purley Way,

[Underlined] CROYDEN [/underlined].

Surrey.

Dear Sirs,

[Underlined] Order No. BS/SC. 10507 (R) [/underlined].

With reference to the above order, and in accordance with your quotation of the 15th December 1944, we would confirm acceptance of the following prices for reconditioning:–

2 off Main Plane Tips to Drg.41507/Sht.2.

[Underlined] @ 27/6d each. [/underlined]

1 off Main Plane Tips to Drg.28507/Sht.19.

[Underlined] @ 27/6d each [/underlined].

1 off Main Plane Tips to Drg.41507/Sht.2.

[Underlined] @ 27/6d/ each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 37/6d. each [/underlined].

1 off Fin L.E. Plating to Drg.28521/309-332

[Underlined] @38/-d each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 45/-d each [/underlined].

1 off Tail Plane Tip to Drg.40618/Sht.3.

[Underlined] @ 35/-d each [/underlined].

1 off Fin Tip to Drg.28521/Sht.6.

[Underlined] @ 50/-d each. [/underlined]

Yours faithfully,

For VICKERS-ARMSTRONGS LIMITED,

Acting for and on behalf of The Minister for Aircraft Production.

COMMERCIAL MANAGER,

Blackpool Works.

PS.

Collection

Citation

“Riveting,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28963.

Item Relations

This item has no relations.