Process check on electrical installation to D.T.D 1029 and inspection instruction A.19

Title

Process check on electrical installation to D.T.D 1029 and inspection instruction A.19

Description

Covers installation of cables, identification of cables, continuity tests, insulation and resistance, bonding and bench work.

Creator

Date

1943-12-28

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10030

Transcription

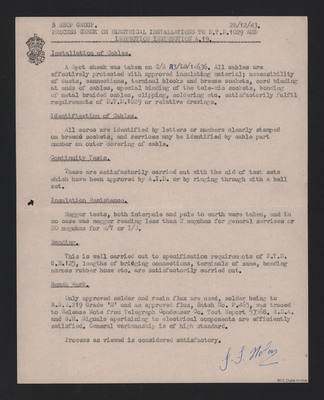

[crest]

B SHOP GROUP. 28/12/43.

[underlined] PROCESS CHECK ON ELECTRICAL INSTALLATIONS TO D.T.D. 1029 AND INSPECTION INSTRUCTION A.19. [/underlined]

[underlined] Installation of Cables. [/underlined]

A Spot check was taken on C/S R3/LB/14636. All cables are effectively protected with approved insulating material; accessibility of ducts, connections, terminal blocks and breeze sockets, cord binding at ends of cables, special binding of the tele-mic sockets, bonding of metal braided cables, clipping, soldering etc. satisfactorily fulfil requirements of D.T.D. 1029 or relative drawings.

[underlined] Identification of Cables. [/underlined]

All cores are identified by letters or numbers clearly stamped on breeze sockets, and services may be identified by cable part number on outer covering of cable.

[underlined] Continuity Tests. [/underlined]

These are satisfactorily carried out with the aid of test sets which have been approved by A.I.D. or by ringing through with a bell set.

[underlined] Insulation Resistance. [/underlined]

Megger tests, both interpole and pole to earth were taken, and in no case was megger reading less than 2 megohms for general services or 20 megohms for W/T or I/C.

[underlined] Bonding. [/underlined]

This is well carried out to specification requirements of D.T.D. G.E. 125, lengths of bridging connections, terminals of same, bonding across rubber hose etc. are satisfactorily carried out.

[underlined] Bench Work. [/underlined]

Only approved solder and resin flux are used, solder being to B.S.S. 219 Grade 'M' and an approved flux, Batch No. P.465, was traced to Release Note from Telegraph Condenser Co. Test Report 53568. R.D.A. and S.M. Signals apertaining [sic] to electrical components are efficiently satisfied. General workmanship is of high standard.

Process as viewed is considered satisfactory.

J.F. Nolan

B SHOP GROUP. 28/12/43.

[underlined] PROCESS CHECK ON ELECTRICAL INSTALLATIONS TO D.T.D. 1029 AND INSPECTION INSTRUCTION A.19. [/underlined]

[underlined] Installation of Cables. [/underlined]

A Spot check was taken on C/S R3/LB/14636. All cables are effectively protected with approved insulating material; accessibility of ducts, connections, terminal blocks and breeze sockets, cord binding at ends of cables, special binding of the tele-mic sockets, bonding of metal braided cables, clipping, soldering etc. satisfactorily fulfil requirements of D.T.D. 1029 or relative drawings.

[underlined] Identification of Cables. [/underlined]

All cores are identified by letters or numbers clearly stamped on breeze sockets, and services may be identified by cable part number on outer covering of cable.

[underlined] Continuity Tests. [/underlined]

These are satisfactorily carried out with the aid of test sets which have been approved by A.I.D. or by ringing through with a bell set.

[underlined] Insulation Resistance. [/underlined]

Megger tests, both interpole and pole to earth were taken, and in no case was megger reading less than 2 megohms for general services or 20 megohms for W/T or I/C.

[underlined] Bonding. [/underlined]

This is well carried out to specification requirements of D.T.D. G.E. 125, lengths of bridging connections, terminals of same, bonding across rubber hose etc. are satisfactorily carried out.

[underlined] Bench Work. [/underlined]

Only approved solder and resin flux are used, solder being to B.S.S. 219 Grade 'M' and an approved flux, Batch No. P.465, was traced to Release Note from Telegraph Condenser Co. Test Report 53568. R.D.A. and S.M. Signals apertaining [sic] to electrical components are efficiently satisfied. General workmanship is of high standard.

Process as viewed is considered satisfactory.

J.F. Nolan

Collection

Citation

J F Nolan, “Process check on electrical installation to D.T.D 1029 and inspection instruction A.19,” IBCC Digital Archive, accessed July 26, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/29002.

Item Relations

This item has no relations.