Process check on protective treatment to D..D 902A

Title

Process check on protective treatment to D..D 902A

Description

Covers cleaning, drying, components and markings and remarks.

Creator

Date

1943-03-23

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10024

Transcription

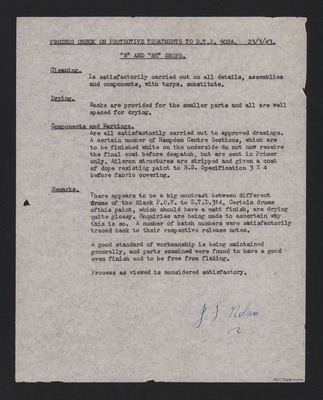

[Underlined] PROCESS CHECK ON PROTECTIVE TREATMENTS TO D.T.D. 902A. 23/3/43.

“B” AND “BE” SHOPS. [/underlined]

[Underlined] Cleaning. [/underlined]

Is satisfactorily carried out on all details, assemblies and components, with turps. substitute.

[Underlined] Drying. [/underlined]

Racks are provided for the smaller parts and all are well spaced for drying.

[Underlined] Components and Markings. [/underlined]

Are all satisfactorily carried out to approved drawings. A certain number of Hampden Centre Sections, which are to be finished white on the underside do not now receive the final coat before despatch, but are sent in Primer only. Aileron structures are stripped and given a coat of dope resisting paint to B.S. Specification 3 X 4 before fabric covering.

[Underlined] Remarks. [/underlined]

There appears to be a big contrast between different drums of the Black P.O.V. to D.T.D.314. Certain drums ofthis [sic] paint, which should have a matt finish, are drying quite glossy. Enquiries are being made to ascertain why this is so. A number of batch numbers were satisfactorily traced back to their respective release notes.

A good standard of workmanship is being maintained generally, and parts examined were found to have a good even finish and to be free from flaking.

Process as viewed is considered satisfactory.

J. F. Nolan

“B” AND “BE” SHOPS. [/underlined]

[Underlined] Cleaning. [/underlined]

Is satisfactorily carried out on all details, assemblies and components, with turps. substitute.

[Underlined] Drying. [/underlined]

Racks are provided for the smaller parts and all are well spaced for drying.

[Underlined] Components and Markings. [/underlined]

Are all satisfactorily carried out to approved drawings. A certain number of Hampden Centre Sections, which are to be finished white on the underside do not now receive the final coat before despatch, but are sent in Primer only. Aileron structures are stripped and given a coat of dope resisting paint to B.S. Specification 3 X 4 before fabric covering.

[Underlined] Remarks. [/underlined]

There appears to be a big contrast between different drums of the Black P.O.V. to D.T.D.314. Certain drums ofthis [sic] paint, which should have a matt finish, are drying quite glossy. Enquiries are being made to ascertain why this is so. A number of batch numbers were satisfactorily traced back to their respective release notes.

A good standard of workmanship is being maintained generally, and parts examined were found to have a good even finish and to be free from flaking.

Process as viewed is considered satisfactory.

J. F. Nolan

Collection

Citation

J F Nolan, “Process check on protective treatment to D..D 902A,” IBCC Digital Archive, accessed September 25, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28998.

Item Relations

This item has no relations.