Process check on splicing to inspection instructions A.34 and A.18

Title

Process check on splicing to inspection instructions A.34 and A.18

Description

Details actions undertaken on inspection.

Creator

Date

1942-10-22

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10020

Transcription

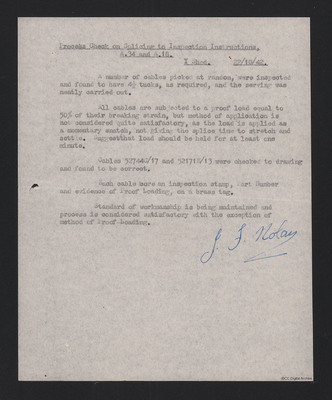

[underlined] Process Check on Splicing to Inspection Instructions A.34 and A.18. Y Shed [/underlined]

[underlined] 22/10/42. [/underlined]

A number of cables picked at random, were inspected and found to have 4 ½ tucks, as required, and the serving was neatly carried out.

All cables are subjected to a proof load equal to 50% of their breaking strain, but method of application is not considered quite satisfactory, as the load is supplied as a momentary snatch, not giving the splice time to stretch and settle. Suggest that load should be held for at least one minute.

Cables 52744C/17 and 52171E/13 were checked to drawing and found correct.

Each cable bore an inspection stamp, Part Number and evidence of proof loading, on a brass tag.

Standards of workmanship is being maintained and process is considered satisfactory with the exception of method of Proof-Loading.

[signature]

[underlined] 22/10/42. [/underlined]

A number of cables picked at random, were inspected and found to have 4 ½ tucks, as required, and the serving was neatly carried out.

All cables are subjected to a proof load equal to 50% of their breaking strain, but method of application is not considered quite satisfactory, as the load is supplied as a momentary snatch, not giving the splice time to stretch and settle. Suggest that load should be held for at least one minute.

Cables 52744C/17 and 52171E/13 were checked to drawing and found correct.

Each cable bore an inspection stamp, Part Number and evidence of proof loading, on a brass tag.

Standards of workmanship is being maintained and process is considered satisfactory with the exception of method of Proof-Loading.

[signature]

Collection

Citation

J F Nolan, “Process check on splicing to inspection instructions A.34 and A.18,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28995.

Item Relations

This item has no relations.