Process check on protective treatment to LTD 902A, Y shed

Title

Process check on protective treatment to LTD 902A, Y shed

Description

Covers process to be conducted.

Creator

Date

1942-09-23

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10017

Transcription

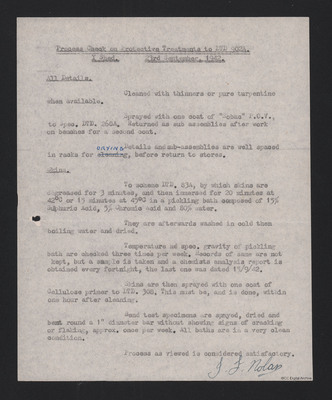

[underlined] Process Check on Protective Treatments to DTD 902A. [/underlined]

[underlined] Y Shed. [/underlined] [underlined] 23rd September, 1942. [/underlined]

[underlined]All Details. [/underlined]

Cleaned with thinners or pure turpentine when available.

Sprayed with one coat of “Sobac” P.O.V., to Spec. DTD. 260A. Returned as sub assemblies after work on benches for a second coat.

Details and sub-assemblies are well spaced in the racks for [deleted] cleaning [/deleted] [/inserted] DRYING [/inserted], before return to stores.

[underlined] Skins. [/underlined]

To scheme DTD. 83A, by which skins are degreased for 3 minutes, and then immersed for 20 minutes at 42°C or 15 minutes at 45°C in a pickling bath composed of 15% Sulphuric Acid, 5% Chromic Acid and 80% water.

They are afterwards washed in cold then boiling water and dried.

Temperature and spec. gravity of pickling bath are checked three times per week. Records of same are not kept, but a sample is taken and a chemist analysis report is obtained every fortnight, the last one was dated 15/9/42.

Skins are then sprayed with one coat of Cellulose primer to DTD. 308. This must be, and is done, within one hour after cleaning.

Bend test specimens are sprayed, dried and bent round a 1” diameter bar without showing signs of cracking or flaking, approx. once per week. All baths are in a very clean condition.

Process as viewed is considered satisfactory

J.F. Nolan

[underlined] Y Shed. [/underlined] [underlined] 23rd September, 1942. [/underlined]

[underlined]All Details. [/underlined]

Cleaned with thinners or pure turpentine when available.

Sprayed with one coat of “Sobac” P.O.V., to Spec. DTD. 260A. Returned as sub assemblies after work on benches for a second coat.

Details and sub-assemblies are well spaced in the racks for [deleted] cleaning [/deleted] [/inserted] DRYING [/inserted], before return to stores.

[underlined] Skins. [/underlined]

To scheme DTD. 83A, by which skins are degreased for 3 minutes, and then immersed for 20 minutes at 42°C or 15 minutes at 45°C in a pickling bath composed of 15% Sulphuric Acid, 5% Chromic Acid and 80% water.

They are afterwards washed in cold then boiling water and dried.

Temperature and spec. gravity of pickling bath are checked three times per week. Records of same are not kept, but a sample is taken and a chemist analysis report is obtained every fortnight, the last one was dated 15/9/42.

Skins are then sprayed with one coat of Cellulose primer to DTD. 308. This must be, and is done, within one hour after cleaning.

Bend test specimens are sprayed, dried and bent round a 1” diameter bar without showing signs of cracking or flaking, approx. once per week. All baths are in a very clean condition.

Process as viewed is considered satisfactory

J.F. Nolan

Collection

Citation

J F Nolan, “Process check on protective treatment to LTD 902A, Y shed,” IBCC Digital Archive, accessed September 25, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28992.

Item Relations

This item has no relations.