Process check on rivetting [sic] to inspection instruction A.24 and M.426, Y and YB shops

Title

Process check on rivetting [sic] to inspection instruction A.24 and M.426, Y and YB shops

Description

Covers storage, control and workmanship

Creator

Date

1942-08-28

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10016

Transcription

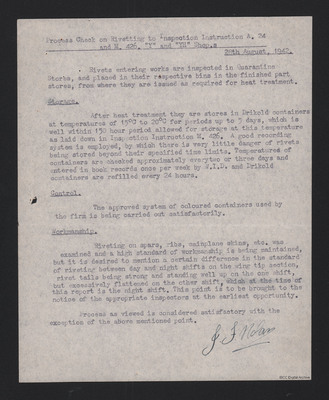

[underlined] Process Check on Rivetting [sic] to Inspection Instructions A. 24 and M. 426. “Y” and “YH” Shop.s [/underlined]

[underlined]28th August, 1942.[/underlined]

Rivets entering works are inspected in Quarantine Stores, and placed in their respective bins in the finished part stores, from where they are issued as required for heat treatment.

[underlined] Storage. [/underlined]

After heat treatment they are stores [sic] in Drikold containers at temperatures of 15°C to 20°C for periods up to 5 days, which is well within 150 hour period allowed for storage at this temperature as laid down in Inspection Instructions M. 246. A good recording system is employed, by which there is very little danger of rivets being stored beyond their specified time limited. Temperatures of containers are checked approximately every two or three days and entered in book records once per week by W.I.D. and Drikold containers are refilled every 24 hours.

[underlined] Control. [/underlined]

The approved system of coloured containers used by the firm is being carried out satisfactorily.

[underlined] Workmanship. [/underlined]

Riveting on spars, ribs, mainplane skins, etc. was examined and a high standard of workmanship is being maintained, but it is desired to mention a certain difference in the standard of riveting between day and night shifts on the wing tip section, rivet tails being strong and standing well up on one shift, but excessively flattened on the other shift, which at the time of this report is the night shift. This point is to be brought to the notice of the appropriate inspectors at the earliest opportunity.

Process as viewed is considered satisfactory with the exception of the above mentioned point.

J.F. Nolan

[underlined]28th August, 1942.[/underlined]

Rivets entering works are inspected in Quarantine Stores, and placed in their respective bins in the finished part stores, from where they are issued as required for heat treatment.

[underlined] Storage. [/underlined]

After heat treatment they are stores [sic] in Drikold containers at temperatures of 15°C to 20°C for periods up to 5 days, which is well within 150 hour period allowed for storage at this temperature as laid down in Inspection Instructions M. 246. A good recording system is employed, by which there is very little danger of rivets being stored beyond their specified time limited. Temperatures of containers are checked approximately every two or three days and entered in book records once per week by W.I.D. and Drikold containers are refilled every 24 hours.

[underlined] Control. [/underlined]

The approved system of coloured containers used by the firm is being carried out satisfactorily.

[underlined] Workmanship. [/underlined]

Riveting on spars, ribs, mainplane skins, etc. was examined and a high standard of workmanship is being maintained, but it is desired to mention a certain difference in the standard of riveting between day and night shifts on the wing tip section, rivet tails being strong and standing well up on one shift, but excessively flattened on the other shift, which at the time of this report is the night shift. This point is to be brought to the notice of the appropriate inspectors at the earliest opportunity.

Process as viewed is considered satisfactory with the exception of the above mentioned point.

J.F. Nolan

Collection

Citation

J F Nolan, “Process check on rivetting [sic] to inspection instruction A.24 and M.426, Y and YB shops,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28991.

Item Relations

This item has no relations.