Process check on heat treatment to inspection instructions

Title

Process check on heat treatment to inspection instructions

Description

Covers cleaning prior to treatment, treatment, quenching, tests and heat treatment of steel to inspection instruction M.407.

Creator

Date

1942-08-24

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10012

Transcription

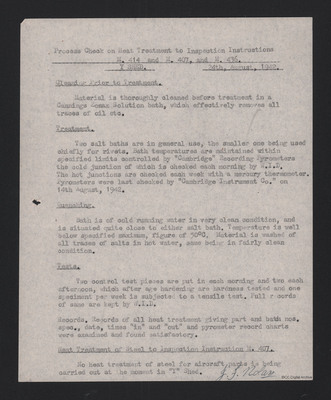

[Underlined] Process Check on Heat Treatment to Inspection Instructions M. 414 and M. 407, and M. 436. [/underlined]

[Underlined] Y SHED. 24th, August, 1942. [/underlined]

[Underlined] Cleaning Prior to Treatment. [/underlined]

Material is thoroughly cleaned before treatment in a Cannings Zonax Solution bath, which effectively removes all traces of oil etc.

[Underlined] Treatment. [/underlined]

Two salt baths are in general use, the smaller one being used chiefly for rivets. Bath temperatures are maintained within specified limits controlled by “Cambridge” Recording Pyrometers the cold junction of which is checked each morning by W.I.D. The hot junctions are checked each week with a mercury thermometer. Pyrometers were last checked by “Cambridge Instrument Co.” on 14th August, 1942.

[Underlined] Quenching. [/underlined]

Bath is of cold running water in very clean condition, and is situated quite close to either salt bath. Temperature is well below specified maximum, figure of 50°C. Material is washed of all traces of salts in hot water, same being in fairly clean condition.

[Underlined] Tests. [/underlined]

Two control test pieces are put in each morning and two each afternoon, which after age hardening are hardness tested and one specimen per week is subject to a tensile test. Full records of same are kept by W.I.D.

Records. Records of all heat treatment giving part and batch nos. spec., date, times “in” and “out” and pyrometer record charts were examined and found satisfactory.

[Underlined] Heat Treatment of Steel to Inspection Instruction M. 407. [/underlined]

No heat treatment of steel for aircraft parts is being carried out at the moment in “Y” Shed.

J.F. Nolan

[Underlined] Y SHED. 24th, August, 1942. [/underlined]

[Underlined] Cleaning Prior to Treatment. [/underlined]

Material is thoroughly cleaned before treatment in a Cannings Zonax Solution bath, which effectively removes all traces of oil etc.

[Underlined] Treatment. [/underlined]

Two salt baths are in general use, the smaller one being used chiefly for rivets. Bath temperatures are maintained within specified limits controlled by “Cambridge” Recording Pyrometers the cold junction of which is checked each morning by W.I.D. The hot junctions are checked each week with a mercury thermometer. Pyrometers were last checked by “Cambridge Instrument Co.” on 14th August, 1942.

[Underlined] Quenching. [/underlined]

Bath is of cold running water in very clean condition, and is situated quite close to either salt bath. Temperature is well below specified maximum, figure of 50°C. Material is washed of all traces of salts in hot water, same being in fairly clean condition.

[Underlined] Tests. [/underlined]

Two control test pieces are put in each morning and two each afternoon, which after age hardening are hardness tested and one specimen per week is subject to a tensile test. Full records of same are kept by W.I.D.

Records. Records of all heat treatment giving part and batch nos. spec., date, times “in” and “out” and pyrometer record charts were examined and found satisfactory.

[Underlined] Heat Treatment of Steel to Inspection Instruction M. 407. [/underlined]

No heat treatment of steel for aircraft parts is being carried out at the moment in “Y” Shed.

J.F. Nolan

Collection

Citation

J F Nolan, “Process check on heat treatment to inspection instructions,” IBCC Digital Archive, accessed July 27, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28988.

Item Relations

This item has no relations.