Process check on electrical installation to D.T.D. 1029 -I.I.

Title

Process check on electrical installation to D.T.D. 1029 -I.I.

Description

Covers installation of cables, approved solder, insulation resistance, identification of cables ands bonding.

Creator

Date

1942-08-19

Temporal Coverage

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10011

Transcription

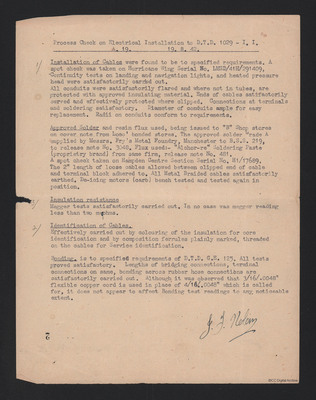

[Underlined] Process Check on Electrical Installation to D.T.D. 1029 – I. I.

A. 19. 19.8.42. [/underlined]

[inserted] 1/ [/inserted] [Underlined] Installation of Cables [/underlined] were found to be to specified requirements. A spot check was taken on Hurricane Wing Serial No. LMSD/41H/291409, Continuity tests on landing and navigation lights, and heated pressure head were satisfactorily carried out.

All conduits were satisfactorily flared and where not in tubes, are protected with approved insulating material. Ends of cables satisfactorily served and effectively protected where clipped. Connections at terminals and soldering satisfactory. Diameter of conduits ample for easy replacement. Radii on conduits conform to requirements.

[Underlined] Approved Solder [/underlined] and resin flux used, being issued to “B” Shop stores on cover note from Loco’ bonded stores. The approved solder Grade A supplied by Messrs. Fry’s Metal Foundry, Manchester to B.S.S. 219, to release note No. 3048. Flux used:- “Alchor-re” Soldering Paste (proprietry [sic] brand) from same firm, release note No. 481.

A spot check taken on Hampden Centre Section Serial No. H1/17689. The 2” length of loose cables allowed between clipped end of cable and terminal block adhered to. All Metal Braided cables satisfactorily earthed. De-icing motors (carb) bench tested and tested again in position.

[inserted] 3/ [/inserted][Underlined] Insulation resistance [/underlined]

Megger tests satisfactorily carried out. In no case was megger reading less than two megohms.

[insertered]2/ [/inserted][Underlined] Identification of Cables. [/underlined]

Effectively carried out by colouring of the insulation for core identification and by composition ferrules plainly marked, threaded on the cables for Service identification.

[Underlined] Bonding. [/underlined] is to specified requirements of D.T.D. G.E. 125. All tests proved satisfactory. Lengths of bridging connections, terminal connections on same, bonding across rubber hose connections are satisfactorily carried out. Although it was observed that 3/16/.0048” flexible copper cord is used in place of 4/16/..0048” which is called for, it does not appear to affect Bonding test readings to any noticeable extent.

J. F. Nolan

[inverted] 2 [/inverted]

A. 19. 19.8.42. [/underlined]

[inserted] 1/ [/inserted] [Underlined] Installation of Cables [/underlined] were found to be to specified requirements. A spot check was taken on Hurricane Wing Serial No. LMSD/41H/291409, Continuity tests on landing and navigation lights, and heated pressure head were satisfactorily carried out.

All conduits were satisfactorily flared and where not in tubes, are protected with approved insulating material. Ends of cables satisfactorily served and effectively protected where clipped. Connections at terminals and soldering satisfactory. Diameter of conduits ample for easy replacement. Radii on conduits conform to requirements.

[Underlined] Approved Solder [/underlined] and resin flux used, being issued to “B” Shop stores on cover note from Loco’ bonded stores. The approved solder Grade A supplied by Messrs. Fry’s Metal Foundry, Manchester to B.S.S. 219, to release note No. 3048. Flux used:- “Alchor-re” Soldering Paste (proprietry [sic] brand) from same firm, release note No. 481.

A spot check taken on Hampden Centre Section Serial No. H1/17689. The 2” length of loose cables allowed between clipped end of cable and terminal block adhered to. All Metal Braided cables satisfactorily earthed. De-icing motors (carb) bench tested and tested again in position.

[inserted] 3/ [/inserted][Underlined] Insulation resistance [/underlined]

Megger tests satisfactorily carried out. In no case was megger reading less than two megohms.

[insertered]2/ [/inserted][Underlined] Identification of Cables. [/underlined]

Effectively carried out by colouring of the insulation for core identification and by composition ferrules plainly marked, threaded on the cables for Service identification.

[Underlined] Bonding. [/underlined] is to specified requirements of D.T.D. G.E. 125. All tests proved satisfactory. Lengths of bridging connections, terminal connections on same, bonding across rubber hose connections are satisfactorily carried out. Although it was observed that 3/16/.0048” flexible copper cord is used in place of 4/16/..0048” which is called for, it does not appear to affect Bonding test readings to any noticeable extent.

J. F. Nolan

[inverted] 2 [/inverted]

Collection

Citation

J F Nolan, “Process check on electrical installation to D.T.D. 1029 -I.I.,” IBCC Digital Archive, accessed July 22, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28987.

Item Relations

This item has no relations.