Process check on anodic oxidation to D.T.D 910A

Title

Process check on anodic oxidation to D.T.D 910A

Description

Covers preparation, electrolyte, cleaning after treatment and tests.

Creator

Date

1942-08-09

Coverage

Language

Type

Format

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10014

Transcription

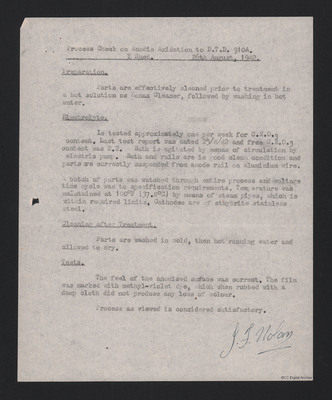

[Underlined] Process Check on Anodic Axidation to D.T.D. 910A. Y Shed. 26th August, 1942. [/underlined]

[Underlined] Preparation. [/underlined]

Parts are effectively cleaned prior to treatment in a hot solution os [sic] Zonax Cleaner, followed by washing in hot water.

[Underlined] Electrolyte. [/underlined]

Is tested approximately one per week for C.R.O.3 content. Last test report was dated 25/8/42 and free C.R.O.3 content was 2.2. Bath is agitated by menas [sic] of circulation by electric pump. Bath and rails are in good clean condition and parts are correctly suspended from anode rail on aluminium wire.

A batch of parts was watched through entire process and voltage time cycle was to specification requirements. Temperature was maintained at 100°F (37.8°C) by means of steam pipes, which is within required limits. Cathodes are of staybrite stainless steel.

[Underlined] Cleaning after Treatment. [/underlined]

Parts are washed in cold, then hot running water and allowed to dry.

[Underlined] Tests. [/underlined]

The feel of the anodised surface was correct. The film was marked with methyl-violet dye, which when rubbed with a damp cloth did not produce any loss of colour.

Process as viewed is considered satisfactory.

J.F. Nolan

[Underlined] Preparation. [/underlined]

Parts are effectively cleaned prior to treatment in a hot solution os [sic] Zonax Cleaner, followed by washing in hot water.

[Underlined] Electrolyte. [/underlined]

Is tested approximately one per week for C.R.O.3 content. Last test report was dated 25/8/42 and free C.R.O.3 content was 2.2. Bath is agitated by menas [sic] of circulation by electric pump. Bath and rails are in good clean condition and parts are correctly suspended from anode rail on aluminium wire.

A batch of parts was watched through entire process and voltage time cycle was to specification requirements. Temperature was maintained at 100°F (37.8°C) by means of steam pipes, which is within required limits. Cathodes are of staybrite stainless steel.

[Underlined] Cleaning after Treatment. [/underlined]

Parts are washed in cold, then hot running water and allowed to dry.

[Underlined] Tests. [/underlined]

The feel of the anodised surface was correct. The film was marked with methyl-violet dye, which when rubbed with a damp cloth did not produce any loss of colour.

Process as viewed is considered satisfactory.

J.F. Nolan

Collection

Citation

J F Nolan, “Process check on anodic oxidation to D.T.D 910A,” IBCC Digital Archive, accessed July 26, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28989.

Item Relations

This item has no relations.