Process check on moulding Perspex to D.T.D.339

Title

Process check on moulding Perspex to D.T.D.339

Description

Covers quarantine inspection, storage, moulding, inspection after moulding and storage,

Creator

Date

1942-11-16

Temporal Coverage

Coverage

Language

Type

Format

Two page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

SNolanJF150621v10021

Transcription

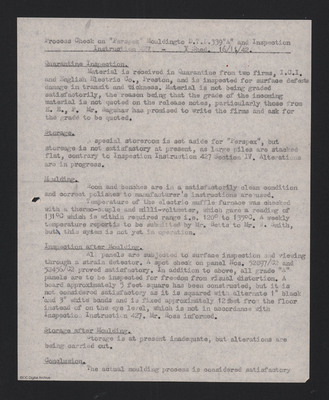

Process Check on “Perspex” Moulding to D.T.D.339 “A” and Inspection Instruction 427 – Y Shed. 16/11/42.

[Underlined] Quarantine Inspection. [/underlined]

Material is received in Quarantine from two firms, I.C.I. and English Electric Co., Preston, and is inspected for surface defects damage in transit and thickness. Material is not being graded satisfactorily, the reason being that the grade of the incoming material is not quoted on the release notes, particularly those from E. E., P. Mr. Bagshaw has promised to write the firms and ask for the grade to be quoted.

[Underlined] Storage. [/underlined]

A special storeroom is set aside for “Perspex”, but storage is not satisfactory at present, as large piles are stacked flat, contrary to Inspection Instruction 427 Section IV. Alterations are in progress.

[Underlined] Moulding. [/underlined]

Room and benches are in a satisfactorily clean condition and correct polishes to manufacturer’s instructions are used.

Temperature of the electric muffle furnace was checked with a thermo-couple and milli-voltmeter, which gave a reading of 131°C which is within required range i.e. 120° to 135°C. A weekly temperature report is to be submitted by Mr. Betts to Mr. W. Smith, but [deleted] h [/deleted] this system is not yet in operation.

[Underlined] Inspection after Moulding. [/underlined]

All panels are subjected to surface inspection snd [sic] viewing through a strain detector. A spot check on panel Nos. 52897/C2 and 52456/C2 proved satisfactory. In addition to above, all grade “A” panels are to be inspected for freedom from visual distortion. A board approximately 5 feet square has been constructed, but it is not considered satisfactory as it is squared with alternate 1” black and 3” white bands and is fixed approximately 12 feet from the floor instead of on the eye level, which is not in accordance with Inspection Instruction 427. Mr. Ross informed.

[Underlined] Storage after Moulding. [/underlined]

Storage is at present inadequate, but alterations are being carried out.

[Underlined] Conclusion. [/underlined]

The actual moulding process is considered satisfactory

[Page break]

but there is ample room for improvement in the grading and in the storage of the material, both before and after moulding.

J F Nolan

[Underlined] Quarantine Inspection. [/underlined]

Material is received in Quarantine from two firms, I.C.I. and English Electric Co., Preston, and is inspected for surface defects damage in transit and thickness. Material is not being graded satisfactorily, the reason being that the grade of the incoming material is not quoted on the release notes, particularly those from E. E., P. Mr. Bagshaw has promised to write the firms and ask for the grade to be quoted.

[Underlined] Storage. [/underlined]

A special storeroom is set aside for “Perspex”, but storage is not satisfactory at present, as large piles are stacked flat, contrary to Inspection Instruction 427 Section IV. Alterations are in progress.

[Underlined] Moulding. [/underlined]

Room and benches are in a satisfactorily clean condition and correct polishes to manufacturer’s instructions are used.

Temperature of the electric muffle furnace was checked with a thermo-couple and milli-voltmeter, which gave a reading of 131°C which is within required range i.e. 120° to 135°C. A weekly temperature report is to be submitted by Mr. Betts to Mr. W. Smith, but [deleted] h [/deleted] this system is not yet in operation.

[Underlined] Inspection after Moulding. [/underlined]

All panels are subjected to surface inspection snd [sic] viewing through a strain detector. A spot check on panel Nos. 52897/C2 and 52456/C2 proved satisfactory. In addition to above, all grade “A” panels are to be inspected for freedom from visual distortion. A board approximately 5 feet square has been constructed, but it is not considered satisfactory as it is squared with alternate 1” black and 3” white bands and is fixed approximately 12 feet from the floor instead of on the eye level, which is not in accordance with Inspection Instruction 427. Mr. Ross informed.

[Underlined] Storage after Moulding. [/underlined]

Storage is at present inadequate, but alterations are being carried out.

[Underlined] Conclusion. [/underlined]

The actual moulding process is considered satisfactory

[Page break]

but there is ample room for improvement in the grading and in the storage of the material, both before and after moulding.

J F Nolan

Collection

Citation

J R Nolan, “Process check on moulding Perspex to D.T.D.339,” IBCC Digital Archive, accessed September 28, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28955.

Item Relations

This item has no relations.