Flight engineer's training notes for a Lancaster

Title

Flight engineer's training notes for a Lancaster

Description

Handwritten notes for Lancaster systems made during Syd Marshall's training to become a flight engineer. It includes detail on start up procedures, fuel and carburettor systems, climb rates, cruising, and cabin heating.

Creator

Language

Format

24 handwritten sheets

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

MMarshallS1594781-150826-01

Transcription

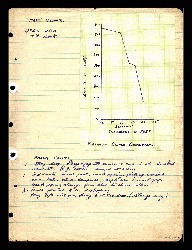

MAX: CLIMB

2850 R.P.M.

+9 Boost

[Inserted graph]

MAXIMUM CLIMB CONDITIONS

ALTITUDE THOUSANDS OF FEET

RATE OF CLIMB

ENGINE FAULTS.

1/ [underlined] Mag drop. [/underlined] Plugs-gap too small or none at all. Cracked insulator. (Life 100hrs changed at 50hrs.)

2/. [underlined] C.B. points. [/underlined] Burnt points, weak spring, pick up corroded. worn [sic] heel, oil or dampness, seized arm, incorrect gap. Weak spring changes from blue to straw collour [sic].

3/. Leads give about 300 drop (approx.)

Mag U/S will give heavy 6 or 800 drop. (Change mag.)

[Page break]

[Table showing fuel consumption of MERLIN XX with R.P.M.]

[Page break]

[Underlined] MET: [/underlined]

[Underlined] Cirrus. [/underlined] 20,000’ – 30,000’ +

[Underlined] Cirro Stratus. [/underlined] 20,000’ – 30,000’ +

[Underlined] Cirro Cumulus. [/underlined] 20,000’ – 30,000’ +

[Underlined] No danger of icing. [/underlined]

[Underlined] Cumulo Nimbus. [/underlined] – Dangerous air currents up to 100mph. Drop in temperature at night & clackling [sic] on intercom.

[Underlined] Cumulous. [sic] [/underlined] up to 20,000’ very bumpy.

[Underlined] Operation of Lancaster fuel system. [/underlined]

1/. [underlined] With all tanks full. [/underlined]

a.) Take-off with No 2 tanks selected.

b.) Climb as required & fly for 20 over 1 hour, still on No 2’s.

c.) After this time change to No 1’s. & switch on No 3’s.

d.) Use No 1’s until contents are approximately level with No 2.

e.) Use No 2 & No 1. alternately to keep contents level until 100 gallons are left in No 2’s.

f.) Drain No 1’s so that No 2’s are left for landing.

[Table inserted]

2/. [Indecipherable word] fuel in No 3’s. [indecipherable word] 2 full, No 1 more than No 2.

a.) Run up & take off as before on No 2’s.

b.) Change to No 1’s after 10 mins.

c.) Use No 1 until level with No 2’s & then alternately.

[Page break]

Points to note.

Ditching exits - which way to turn handle.

Crash axes. – position.

Controls Port side.

U/C warning lamp.

George pressure gauge.

[Page break]

[Underlined] Measurement of Fuel Consumption. [/underlined]

[Table of fuel consumption]

In range flying G.P.H. gives no indication of how the A./C [ aircraft] has been handled.

A./C travels 300 track miles at an average G.P.H of & 180.

I.A.S of 167 at 12000 feet. Find T.M.P.G. & A.M.P.G.

a) in still air.

b.) in following wind of 50 mph.

c.) in head wind of 50mph.

[Calculations]

[Page break]

[Underlined] G.S.T. [/underlined]

[Underlined] NAVIGATION [/underlined]

[Underlined] 3 Navigation methods [/underlined] – Astro nav: D.R.compass. Maps.

[Underlined] Plotting chart. [/underlined] - Mercators.

[Underlined] Topographical [/underlined] - Conical.

[Underlined] Bearing. [/underlined] – line of direction – compass, true magnetic.

[Underlined] Rhumb line [/underlined] – line on mercators map, cutting all meridians at the same angle & giving a constant bearing.

[Underlined] Prime meridian [/underlined] – from which all others are taken.

[Underlined] Position. [/underlined] give lat: & long: or map reference.

[Underlined] Isogomal [/underlined] – joins all points of equal variation.

[Underlined] Isobar. [/underlined] – imaginary line joining all points of equal barometric pressure.

[Underlined] Air speed [/underlined] – relative to air flow.

[Underlined] Drift [/underlined] angle between course & track.

[Underlined] Variation [/underlined] angle between true & magnetic.

[Underlined] Compass. [/underlined]

[Underlined] Main parts. [/underlined] Bowl, grid ring, Magnetic system.

[Underlined] Oscilation [/underlined] of needle prevented by alcohol & damping wires

[Underlined] Luber line. [/underlined] fixed datum. placed fore & aft of A/C.

3/. 400 or less in No 1’s & No 2’s full.

a.) Take-off & continue on No 2’s for one hour.

b.) Change to No 1’s & alternate each hour.

[Underlined] Calculating T.A.S. [/underlined]

With static vents I.A.S. = R.A.S.

I.A.S. = Speed read on dial when instrument error has been taken into account.

At sea level I.A.S. = T.A.S.

At altitude T.A.S. x altitude correction factor = T.A.S.

[Table showing altitude correction factors for Thousands of feet]

[Page break]

[Diagram of STROMBERG. CARB:]

[Page break]

[Underlined] STROMBERG CARBURETTOR [/underlined]

Air pressure led to chamber ‘B’ from boost venturi, being at a lower pressure that [sic] that led to ‘A’ from Impact tubes via A.M.C, causes diaphragm to bulge, & so open poppet valve connected to it, allowing fuel to flow into chamber ‘D’. With ‘C’ at nozzle pressure (5lb/□.), pressure builds up in ‘D’ until stab of equilibrium is reach [sic] in pressure difference in both sets of chambers. Thus an increased depression in ‘B’ will be transmitted to ‘D’ & cause a greater amount of fuel to flow.

A build up of pressure in ‘D’ will also be felt on the enrichment needle diaphragm, opening needle & allowing extra fuel to flow into delivery.

[Underlined] Vapour vent. [/underlined] is led back [sic] No 2 tank from petrol recovering chamber.

[Underlined] Accelerator pump. [/underlined] any increase in pressure above butterflies due to throttle opening is felt on pump diaphragm causing it to bulge & force out additional fuel, it recharges again under conditions of low pressure.

[Underlined] Automatic mixture control unit [/underlined]. air at intake pressure is led to an aneroid operated A.M.C. situated in the pipeline from the impact tubes to chamber ‘A’. As air pressure decreases, the aneroid expands, moving down the needle and reducing pressure to ‘A’. A bleed from ‘A’ to ‘B’ allowing a constant flow of air ensures operation of this. This in turn reduces the amount of valve opening & ؞ the amount of fuel allowed to pass from spray nozzle.

Fuel is pumped into carb at pressure of 15lbs/□”.

[Underlined] RUNNING UP [/underlined].

[Numerical points obscured]

Slow run 1200 – 1500 R.P.M. Check mags for dead cut.

Temperatures to 15°C or rise of 5°C (oil.) 60°.C. (Coolant.)

Inserted] Open rad: shutters.

Select zero boost. (2,300. rpm.)

Select 2,000 R.P.M.

Advance throttle to obtain +4lbs boost. No increase in R.P.M should indicate that C.S.U. is functioning correctly.

Raise R.P.M. to max: No change in boost will indicate boost control working correctly.

Advance throttle to gate. (2800. +9.)

[Page break]

[Underlined] Coolant temperatures. [/underlined] °C.

Maximum for take-off 60°.

Max: for cruising 105° - 115° Short period only.

Max: for climb, level flight or combat 125° (135° for 5 mins.)

Normal 80° - 100° C.

[Underlined] ANCILLIARIES DRIVEN FROM ENGINES [/underlined]

[Table showing each ancilliary part driven from each of the 4 engines]

D.C. Generators & Dowty hydraulic pumps are in parallel, if either engine cuts out, hydraulic & electrical services continue to operate at half capacity.

[Underlined] LUBRICATION SYSTEM. [/underlined]

[Missing word] [Underlined] tank. [/underlined] – capacity 42 [number deleted] gallons. Filled to a maximum of 37 1/2 gallons of oil. Normally about 30 gallons.

[Underlined] Consumption [/underlined] – Normal 1 1/2 or 1 gallons/hrs. [sic] Maximum 2 3/4 gallons/hour. Hot well, fitted inside oil tank to facilitate rapid heating of oil in engine without the need for heating entire contents of tank. Base of hot well is [underlined] not [/underlined] drilled so as to [sic] for a stack pipe. This allows at least 2 gallons of oil for feathering purposes.

[Underlined] Filler caps [/underlined] – port side, beneath leading edge.

[Underlined] Dip sticks [/underlined] long for inners, short for outers, due to tank shape.

[Page break]

[Underlined] LANCASTER ENGINES. MERLIN 20 & 28 [/underlined]

[Underlined] Leading particulars. [/underlined]

[Underlined] S/C Gears. [/underlined] M = 8.15 – 1. S = 9.49 – 1.

[Underlined] Rated altitudes [/underlined] M = 10,000 feet. S = 17,500 feet.

[Underlined] Prop rotation [/underlined] – Right hand tractor.

[Underlined] C/Shaft. [/underlined] – Left hand (from rear.)

[Underlined] Consumption [/underlined] - T.O 115 gallon per hour/engine. Cruising 64 gallon per hour/engine.

[Underlined] Oil [/underlined] D.T.D 472B. Grade “X”.

[Underlined] Coolant. [/underlined] – 70% Water – 30% Glycol. (D.T.D. 344. A.)

[Underlined] Firing Order [/underlined] A. 1 4 2 6. 3 5 B. 6 3 5 1 4 2.

[Underlined] Propellor [sic] [/underlined] D.H. Hydromatic. Type 5. 500.

[Underlined] ENGINE CONDTIONS & LIMITATIONS. [/underlined]

[Table showing Engine conditions with associated limitations on R.P.M., Boost, Gear and Time]

[Underlined] Oil temperatures in °C. [/underlined]

Minimum for take-off. 15°C (or increase of 5° if above.)

Max for cruising. 90°C. (100° short period emergency.)

Emergency max. 105°C – Danger point.

[Underlined] Oil pressures in lbs/□” [/underlined]

High pressure 45 – 90.

minimum 30.

Low pressure 6 – 10.

[Page break]

[Underlined] OPERATIONAL CLIMB [/underlined]

[Graph showing throttle revs., airspeed and heights]

Select 2650. + 4. at end of take-off climb to full throttle height when throttle lever will be at the gate. Change to ‘S’ gear leaving throttle at gate & bring revs up to 2850. Boost will rise to +9. Climb at these settings irrespective of drop off in boost above R.A. until 20,000 feet is reached. Fly for sufficient time to use 150 gals (1,000 lbs) or 1hr to lighten plane before continuing climb. I.A.S. 160 mph.

[Underlined] ENDURANCE FLYING [/underlined] 3,000’. & below.

1800 r.p.m. I.A.S. 135m.p.h. Boost? Maintain flying speed & rpm by varying throttle.

[Page break]

[Underlined] MAXIMUM CLIMB [/underlined]

[Graph showing settings in maximum climb at different heights]

Select 2850 +9 after end of initial take off climb. Boost will be maintained automatically up to R.A. (10,000’.) When boost has fallen by 3lbs change to ‘S’ gear. [ word missing] will take control until R.A in ‘S’ gear (17,500’.) from then on boost will gradually fall off.

[Underlined] CRUISING OVER 3,000’. [/underlined]

[Underlined] Ideal conditions, [/underlined] throttle lever at gate, piston forward, butterfly wide open. Cut down rpm to get 160-170 I.A.S.

If revs in [deleted letter] ‘S’ are below 2,300 change to ‘M’.

If revs in ‘M’ are above 2500 change to ‘S’.

Max permissible R.P.M. in ‘M’. above 12,000’ is 2,500.

Never exceed +4lbs boost. Always fly at recommended I.A.S. ‘M’ or ‘S’ 160-170 mph. Always fly at recommended altitude 8,000’ to 16,000’. Fly in cold air whenever possible (intakes.)

[Page break]

9/. Momentarily take throttle through gate. (3,000 +12.)

10/. Throttle back to +9. Check mag drop. Should not exceed 100 rpm.

11/. Throttle back to 0 boost.

12/. Check 2 speed blower – momentary increase in boost & drop in R.P.M. (red light should come on)

13/. Throttle back to 1500 rpm. Snap throttle back to Slow running to check for engine cut out ([underlined] 20 [/underlined]-450 to 650) (28-600-800.)

14/. Advance throttles slightly to clear engine.

15/. I.C.O to OFF position.

16/. Mags off as prop stops turning, petrol off & I.C.O to on-position.

[Deleted] [Underlined] STARTING UP. [/underlined]

1/. Check position of cross-balance cock, note freedom of movement.

2/. Ground – Flight switch to flight.

3/. U/C locked down, bomb doors closed, flaps neutral.

4/. U/C indicator & flap indicator ‘ON’. [/deleted]

[Underlined] STARTING UP. [/underlined]

1/. Cross balance cock [underlined] OFF. [/underlined]

2/. G/F switch to [underlined] Flight. [/underlined]

3/. Switch on Engineers [sic] panel. [underlined] ON. [/underlined] Check fuel contents & warning lights (if fitted.) Select tanks & switch on booster pumps (No 2.)

4/. U/C lever [underlined] locked down [/underlined]. Bomb doors [underlined] closed [/underlined], flaps [underlined] neutral [/underlined].

5/. U/C & flap indicators [underlined] ON. [/underlined]

6/. Brake pressure min: of [underlined] 150lbs. [/underlined]

7/. Boost out out [sic] [underlined] up (not pulled.) [/underlined].

8/. S/Ch in [underlined] ‘M’ Gear. [/underlined]

9/. Air intakes [underlined] cold [/underlined].

10/. Throttles [underlined] 3/4" open [/underlined].

11/. Props [underlined] max. R.P.M [/underlined].

12/. Ground Flight switch to [underlined] Ground. [/underlined]

13/. I.C.O to [underlined] I.C.OFF position. [/underlined]

14/. Master fuel cocks [underlined] ON. [/underlined]

15/. Ignition & Booster coil [underlined] ON. [/underlined]

16/. Contact ground crew (External acc & priming.)

17/. Press starter button & Put [sic] I.C.O [underlined] ON [/underlined] as engine fires. (OFF again if engine fails to pick up. [sic]

[Page break]

[Underlined] SUPERCHARGER [/underlined]

S/Ch fitted to give extra power at sea level & maintain sea level power at altitudes. Centrifugal impellor [sic] driven from rear of crankshaft. It contains one upper centrifugally loaded clutch for m. gear & two lower pack clutch gears for ‘S’ gear. Clutches allow gear changing & absorb high loads during acceleration. Cam shaft turned by piston, operated by scavenge oil, changes gears by means of forked rods. [deleted] Sevo [/deleted] Servo piston is controlled by a rotary valve, which is in turn operated by a pneumatic jack which is electrically controlled.

[Underlined] Boost Regulator maintenance. [/underlined]

Every 50 hours – (minor inspection) a teaspoonful of Anti freeze type ‘A’ oil to lubricate landed valve & sleeve.

[Underlined] Economical Climb [/underlined]. Booster pumps off at 2000’.

I.A.S. 160 – 170. Boost +4. R.P.M. will vary with altitude of aircraft. Above 10,000’ boost will have to be maintained by manual opening of throttle. Change into ‘S’ gear when boost falls by 2 lbs below that desired. Booster pumps on at 17,000’.

[Underlined] DISPERSAL DRILL [/underlined]

[Underlined] PRE-STARTING. [/underlined]

[Numerical points obscured]

Chocks in position, Pitot head, Static vents, Cockpit, turret & wheel covers off cable cutter covers. Jury struts.

Visual inspection of hinged leading edge, engine cowlings, tyres for creep, cuts, etc: & rudder hinges. Oleo leg extensions.

Check state of fuel tanks from Form 700.

Enter A/C & check.

[Numerical points iobscured]

[Underlined] Axes [/underlined], First aid kit, external dingy [sic] release, dip sticks, D.R. Compass for freedom of movement.

Fire extinguishers. Portable oxygen bottles.

Pyrotechnics – flame floats & equipment properly stowed.

Security of hatches.

Oxygen main cock [underlined] ON [/underlined].

Emergency air. 1200lbs/□”.

Initial hydraulic acc pressure.

G/F switched to Flight.

Cross feed cock. off.

Check fuel contents gauges & booster pumps with ammeter.

Select No 2 tanks

[Page break]

12/. Test trimmers for freedom of movement.

13/. U/C locked down.

[Underlined] Pilot & Engineer. [/underlined]

1/. Brakes ON note pressure.

2/. Bomb doors closed.

3/. Mixer box to I/C position.

4/. Auto control clutches IN.

5/. Flap gauge & U/C indicator lights ON.

6/. Altimeter to zero.

7/. Flap lever in Neutral.

8/. Air intakes to cold.

9/. R.P.M. Levers to max.

10/. S/Ch to ‘M’.

11/. Master switch to Ground.

12/. Booster pumps ON.

13/. Contact ground crew.

14/. I.C.O. to off, master fuel cock ON. Ignition & booster coil on.

15/. As engine fires switch on I.C.O. Booster coil off. Oil pressure.

16/. Warm up 1200 to 1500 rpm.

17/. Check mags for dead cut. [Underlined] SEE BACK. [/underlined]

[Underlined] Cut-out [/underlined] used for take-off if load exceeds 61.500 lb A.U.W. if this is to be used it should be checked on run up. Put cut-out at slow running & open up to gate just long enough to note boost.

Captain of air-craft calls up each member of A/C in turn to check equipment.

[Underlined] Taxying [/underlined], follow ground crews [sic] signals, Engineer watches Stbd: side of track. Rear gunner watches for overtaking aircraft. Test brakes. [Underlined] Never [/underlined] turn with a wheel locked.

Keep inboards at 1000 (approx.) rpm & use outers to turn etc:

Use brakes as little as possible with safety.

[Underlined] Take Off. [/underlined]

Pilot gives order – pause & carry out.

1/. Engines opened up to clear.

2/. Opened up to T.O.B. on “Ready for take off”. After check temps etc:

3/.

4/.

5/. 100’ U/C up.

6/. 1,000’ return cut out & Select +9, 2850 r.p.m.

[Page break]

7/. Flaps up slowly as possible while Pilot re-trims.

8/. Select climbing R.P.M. & Boost.

9/. 2,000’ booster pumps off.

10/. 4,000’ oxygen on (night only).

[Table of Pilot and Engineer intercoms and actions for take off]

[Underlined] ECONOMICAL CLIMB [/underlined]

[Graph of heights, throttle settings, boost & rpm]

Select 2650r.p.m & +4 boost when Pilot asks for climbing power. This will be controlled by regulator up to R. ALT (10,000’.) above this it is maintained by manually opening throttle until lever is at gate. When boost then falls by 2 lbs, change into [deleted] s [/deleted] ‘S’ gear. & continue to control manually at +4 up to F.T.H in ‘S’.

[Page break]

[Underlined] LOW LEVEL CRUISING [/underlined]

Reduce R.P.M to 2650.

Select +4 boost.

Select 1800 r.p.m.

Never use more than + 4 boost. If Boost tends to rise throttle back. [Underlined] Ignore I.A.S. [/underlined]

[Underlined] Target area [/underlined]

Select tanks containing most fuel. Switch on 4 main booster pumps. Continue cruising conditions.

[Underlined] Return [/underlined] ???([underlined] 3 or 4 engines. [/underlined])

Trim to desired angle of descent (Pilot.)

Boost below + 4.

160 I.A.S.

Control I.A.S. by r.p.m.

2,300 in ‘S’ [deleted letters] raise to 2,500, change to ‘M’.

When 1800 r.p.m is reached I.A.S will rise – carry on.

Below 3,000’ keep boost below + 4 with throttle ignore I.A.S.

[Underlined] Descent. (2 engines.) [/underlined] ??!!!!*√∏*

Will maintain height of below 10,000 ft

R.P.M. 2850. Boost + 9. I.A.S. ? Change ‘M’ 12,000ft.

If height is lost with +9 in ‘M’ pull cut out.

[Underlined] Landing [/underlined]

[Inserted] Auto control “out”. Clutch “out”. [/inserted]

Pre landing check. S/Ch in ‘M’. Air intakes cold. Brake Pressure 150 lbs/□” (minimum). Booster pumps [underlined] on [/underlined]. Select tanks with most fuel.

[Diagram of approach to landing showing flaps, rpm, speed and undercarriage instructions.]

[Page break]

[Underlined] AFTER LANDING [/underlined]

Select flaps up.

Open rad: flaps.

Check brake pressure.

Couple up Aldis lamp if required.

At dispersal check mags & S/Ch blower.

I.C.O off mags off. Master & Selector cocks off.

Switch off electrical services & G/F switch to “flight”.

Select flaps down.

Return I.C.O. to [underlined] ON [/underlined]. Rad: flaps to auto.

[Underlined] DE [inserted letter] S [/inserted letter] CENT. [/underlined]

[Diagram showing angle of descent with booster instructions, I.A.S. and R.P.M. instructions.

[Page break]

[Underlined] Clark’s viscosity valve [/underlined].

Allows rapid warming up of oil by means of bye-passing [sic] the oil cooler until oil has reached a temperature which allows free lubrication of engine & then controls minimum temperature of oil.

[Underlined] Overheating of oil [/underlined]. Blocked impact tubes. Blocked radiator. Shortage of oil.

[Underlined] Loss of oil pressure. [/underlined] – No oil, gauge U/S, damaged capillary. Shared pump drive.

[Underlined] Low oil pressure. [/underlined] – Worn bearings (main or big end.) Faulty gauge. Dirt under relief valve. Dirty filter. Leaky pipes. Damaged or worn pump gears.

[Underlined] Fluctuating pressure [/underlined]. Air bleeding in suction side of pump.

[Underlined] Dry Sump system [/underlined] 1. Pressure & 2. Scavenge pumps. Scavenge pumps have 20% greater capacity than pressure pumps to maintain a dry sump.

Oil flows from tank to pressure pump.

From 4 crankcase web into gallery pipe & so crankshaft bearings & forward to c.s.v & Pesco pump.

Branch line from pump lubricates fuel pump [inserted] seal [/inserted] & on S.I. engine, the Heywood compressor also.

[Underlined] Low pressure [/underlined] – through external pipe to reduction gear. Also rearward to cam shaft, S/C rear bearing, S/C gears. etc: Fuel, oil & water pump lubricated by the fluid they carry. Linkwork at rear hand lubricated.

[Underlined] Lower spindle of coolant pump [/underlined] is greased by groove cup. (Silcaline grease.)

Scavenge system taken from sump through filters to S/Ch gear change (if ‘20’ to carb butterflies) then to viscosity valve back to tank.

[Underlined] Coolant System [/underlined]

[Underlined] Glycol [/underlined] to reduce freezing point. (-14°C.) Water is best coolant.

[Underlined] Drain [/underlined] at base of pump & radiator screws.

[Underlined] Capacity [/underlined] approx 12 gallons.

[Underlined] Thermostat [/underlined] at outlet of header tank. Allows coolant to warm up quickly & controls the minimum temperature. Coolant passes through radiator from 85° all coolant goes through at 105°.

[Underlined] Radiator [/underlined] pressure tested to 30 lbs/□”.

[Page break]

[Underlined] Cabin heating [/underlined]. From ‘B’ block return to inlet side of pump.

[Underlined] Carburettor [/underlined] jacket from ‘A’ block return to inlet side of pump.

[Underlined] Circulation [/underlined] – Header tank, thermostat, (radiator or bye [sic] pass)

Pump, - inlet rails, through blocks to outlet rails, back to header tank.

[Underlined] Pressure system, [/underlined] if punctured temperature of coolant will fall to boiling point for that height. When coolant becomes short, temp: will remain the same but oil temp: will rise. Pressure is caused by heat generated in system & allows running temperatures of over 100°C. Pressure is maintained by [underlined] Teddington thermostatic [/underlined] relief valve. Blows off at max: of 30 lbs. Allows air to pass in at 2 1/2 lbs below in atmospheric pressure. Keeps pressure sufficient to stop boiling.

[Underlined] Temp: gauge [/underlined] connection & connection to thermostatic rad: shutter control at outlet of header tank.

[Underlined] Rad: flaps [/underlined] open 105°C, close 99°C.

[Underlined] Thermostat [deleted] ic [/deleted] [/underlined] becomes operative & starts to pass coolant through radiator at 85°C & all coolant passes through rad at 105°C.

[Underlined] S.U. Carb: [/underlined] A.V.T. 40/

[Underlined] Setting of needles [/underlined] should be checked against measurements and conditions laid down in A.Ps. (AP1590. G. VOL I.)

[Underlined] Slow running [/underlined]. Fuel from main jet taken up S.R. tube air is bled into top of tube to emulsify fuel and out to edge of butterflies (when nearly closed) via S.R. box.

R.P.M. 456 – 600.

[Underlined] Diffusors [/underlined] each has a disc jet at its base though which fuel must flow. It is regulated here by needle valves. Air is admitted to top of diffuser at intake pressure & forms an emulsion which passes via the main delivery to the choke.

[Underlined] Accelerator pump [/underlined] used to overcome time lag of fuel, in reaching induction when throttle is opened.

[Underlined] Enrichment aneroid [/underlined] does not move until Boost pressure exceeds +4 1/2 lbs, beyond this needle is progressively lifted to give rich mixture.

[Underlined] Altitude mixture control [/underlined]. progressively reduces size of jet to keep mixture strength constant.

[Underlined] Hot coolant [/underlined] is passed round the jacket, & scavenge oil through the butterfies [sic] to prevent icing

[Page break]

[Graph of BHP and Altitude in 1000ft.]

[Page break]

[Graph of MERLIN XX & XXII WEAK MIXTURE CONDITIONS ‘M’ GEAR & ‘S’ GEAR with B.H.P. and Altitude in 1000ft.]

[Page break]

[Calculations]

[Page break]

Fuel system 150.

Engine General 50.

Carburettor & Propellor 100.

Engine ground testing 50.

Engine air handling 150.

Log keeping 50.

Airframe general 50.

Jettisoning, ditching, dingies [sic] 100.

Hydraulics, Pneumatics, Electrics 100.

Anti icing, Oxygen, F.Es . inspection of A/C. 100.

Manufacturers [sic] course 50.

Fuel calculation (consumption.) 50.

Total 4,000.

2850 R.P.M.

+9 Boost

[Inserted graph]

MAXIMUM CLIMB CONDITIONS

ALTITUDE THOUSANDS OF FEET

RATE OF CLIMB

ENGINE FAULTS.

1/ [underlined] Mag drop. [/underlined] Plugs-gap too small or none at all. Cracked insulator. (Life 100hrs changed at 50hrs.)

2/. [underlined] C.B. points. [/underlined] Burnt points, weak spring, pick up corroded. worn [sic] heel, oil or dampness, seized arm, incorrect gap. Weak spring changes from blue to straw collour [sic].

3/. Leads give about 300 drop (approx.)

Mag U/S will give heavy 6 or 800 drop. (Change mag.)

[Page break]

[Table showing fuel consumption of MERLIN XX with R.P.M.]

[Page break]

[Underlined] MET: [/underlined]

[Underlined] Cirrus. [/underlined] 20,000’ – 30,000’ +

[Underlined] Cirro Stratus. [/underlined] 20,000’ – 30,000’ +

[Underlined] Cirro Cumulus. [/underlined] 20,000’ – 30,000’ +

[Underlined] No danger of icing. [/underlined]

[Underlined] Cumulo Nimbus. [/underlined] – Dangerous air currents up to 100mph. Drop in temperature at night & clackling [sic] on intercom.

[Underlined] Cumulous. [sic] [/underlined] up to 20,000’ very bumpy.

[Underlined] Operation of Lancaster fuel system. [/underlined]

1/. [underlined] With all tanks full. [/underlined]

a.) Take-off with No 2 tanks selected.

b.) Climb as required & fly for 20 over 1 hour, still on No 2’s.

c.) After this time change to No 1’s. & switch on No 3’s.

d.) Use No 1’s until contents are approximately level with No 2.

e.) Use No 2 & No 1. alternately to keep contents level until 100 gallons are left in No 2’s.

f.) Drain No 1’s so that No 2’s are left for landing.

[Table inserted]

2/. [Indecipherable word] fuel in No 3’s. [indecipherable word] 2 full, No 1 more than No 2.

a.) Run up & take off as before on No 2’s.

b.) Change to No 1’s after 10 mins.

c.) Use No 1 until level with No 2’s & then alternately.

[Page break]

Points to note.

Ditching exits - which way to turn handle.

Crash axes. – position.

Controls Port side.

U/C warning lamp.

George pressure gauge.

[Page break]

[Underlined] Measurement of Fuel Consumption. [/underlined]

[Table of fuel consumption]

In range flying G.P.H. gives no indication of how the A./C [ aircraft] has been handled.

A./C travels 300 track miles at an average G.P.H of & 180.

I.A.S of 167 at 12000 feet. Find T.M.P.G. & A.M.P.G.

a) in still air.

b.) in following wind of 50 mph.

c.) in head wind of 50mph.

[Calculations]

[Page break]

[Underlined] G.S.T. [/underlined]

[Underlined] NAVIGATION [/underlined]

[Underlined] 3 Navigation methods [/underlined] – Astro nav: D.R.compass. Maps.

[Underlined] Plotting chart. [/underlined] - Mercators.

[Underlined] Topographical [/underlined] - Conical.

[Underlined] Bearing. [/underlined] – line of direction – compass, true magnetic.

[Underlined] Rhumb line [/underlined] – line on mercators map, cutting all meridians at the same angle & giving a constant bearing.

[Underlined] Prime meridian [/underlined] – from which all others are taken.

[Underlined] Position. [/underlined] give lat: & long: or map reference.

[Underlined] Isogomal [/underlined] – joins all points of equal variation.

[Underlined] Isobar. [/underlined] – imaginary line joining all points of equal barometric pressure.

[Underlined] Air speed [/underlined] – relative to air flow.

[Underlined] Drift [/underlined] angle between course & track.

[Underlined] Variation [/underlined] angle between true & magnetic.

[Underlined] Compass. [/underlined]

[Underlined] Main parts. [/underlined] Bowl, grid ring, Magnetic system.

[Underlined] Oscilation [/underlined] of needle prevented by alcohol & damping wires

[Underlined] Luber line. [/underlined] fixed datum. placed fore & aft of A/C.

3/. 400 or less in No 1’s & No 2’s full.

a.) Take-off & continue on No 2’s for one hour.

b.) Change to No 1’s & alternate each hour.

[Underlined] Calculating T.A.S. [/underlined]

With static vents I.A.S. = R.A.S.

I.A.S. = Speed read on dial when instrument error has been taken into account.

At sea level I.A.S. = T.A.S.

At altitude T.A.S. x altitude correction factor = T.A.S.

[Table showing altitude correction factors for Thousands of feet]

[Page break]

[Diagram of STROMBERG. CARB:]

[Page break]

[Underlined] STROMBERG CARBURETTOR [/underlined]

Air pressure led to chamber ‘B’ from boost venturi, being at a lower pressure that [sic] that led to ‘A’ from Impact tubes via A.M.C, causes diaphragm to bulge, & so open poppet valve connected to it, allowing fuel to flow into chamber ‘D’. With ‘C’ at nozzle pressure (5lb/□.), pressure builds up in ‘D’ until stab of equilibrium is reach [sic] in pressure difference in both sets of chambers. Thus an increased depression in ‘B’ will be transmitted to ‘D’ & cause a greater amount of fuel to flow.

A build up of pressure in ‘D’ will also be felt on the enrichment needle diaphragm, opening needle & allowing extra fuel to flow into delivery.

[Underlined] Vapour vent. [/underlined] is led back [sic] No 2 tank from petrol recovering chamber.

[Underlined] Accelerator pump. [/underlined] any increase in pressure above butterflies due to throttle opening is felt on pump diaphragm causing it to bulge & force out additional fuel, it recharges again under conditions of low pressure.

[Underlined] Automatic mixture control unit [/underlined]. air at intake pressure is led to an aneroid operated A.M.C. situated in the pipeline from the impact tubes to chamber ‘A’. As air pressure decreases, the aneroid expands, moving down the needle and reducing pressure to ‘A’. A bleed from ‘A’ to ‘B’ allowing a constant flow of air ensures operation of this. This in turn reduces the amount of valve opening & ؞ the amount of fuel allowed to pass from spray nozzle.

Fuel is pumped into carb at pressure of 15lbs/□”.

[Underlined] RUNNING UP [/underlined].

[Numerical points obscured]

Slow run 1200 – 1500 R.P.M. Check mags for dead cut.

Temperatures to 15°C or rise of 5°C (oil.) 60°.C. (Coolant.)

Inserted] Open rad: shutters.

Select zero boost. (2,300. rpm.)

Select 2,000 R.P.M.

Advance throttle to obtain +4lbs boost. No increase in R.P.M should indicate that C.S.U. is functioning correctly.

Raise R.P.M. to max: No change in boost will indicate boost control working correctly.

Advance throttle to gate. (2800. +9.)

[Page break]

[Underlined] Coolant temperatures. [/underlined] °C.

Maximum for take-off 60°.

Max: for cruising 105° - 115° Short period only.

Max: for climb, level flight or combat 125° (135° for 5 mins.)

Normal 80° - 100° C.

[Underlined] ANCILLIARIES DRIVEN FROM ENGINES [/underlined]

[Table showing each ancilliary part driven from each of the 4 engines]

D.C. Generators & Dowty hydraulic pumps are in parallel, if either engine cuts out, hydraulic & electrical services continue to operate at half capacity.

[Underlined] LUBRICATION SYSTEM. [/underlined]

[Missing word] [Underlined] tank. [/underlined] – capacity 42 [number deleted] gallons. Filled to a maximum of 37 1/2 gallons of oil. Normally about 30 gallons.

[Underlined] Consumption [/underlined] – Normal 1 1/2 or 1 gallons/hrs. [sic] Maximum 2 3/4 gallons/hour. Hot well, fitted inside oil tank to facilitate rapid heating of oil in engine without the need for heating entire contents of tank. Base of hot well is [underlined] not [/underlined] drilled so as to [sic] for a stack pipe. This allows at least 2 gallons of oil for feathering purposes.

[Underlined] Filler caps [/underlined] – port side, beneath leading edge.

[Underlined] Dip sticks [/underlined] long for inners, short for outers, due to tank shape.

[Page break]

[Underlined] LANCASTER ENGINES. MERLIN 20 & 28 [/underlined]

[Underlined] Leading particulars. [/underlined]

[Underlined] S/C Gears. [/underlined] M = 8.15 – 1. S = 9.49 – 1.

[Underlined] Rated altitudes [/underlined] M = 10,000 feet. S = 17,500 feet.

[Underlined] Prop rotation [/underlined] – Right hand tractor.

[Underlined] C/Shaft. [/underlined] – Left hand (from rear.)

[Underlined] Consumption [/underlined] - T.O 115 gallon per hour/engine. Cruising 64 gallon per hour/engine.

[Underlined] Oil [/underlined] D.T.D 472B. Grade “X”.

[Underlined] Coolant. [/underlined] – 70% Water – 30% Glycol. (D.T.D. 344. A.)

[Underlined] Firing Order [/underlined] A. 1 4 2 6. 3 5 B. 6 3 5 1 4 2.

[Underlined] Propellor [sic] [/underlined] D.H. Hydromatic. Type 5. 500.

[Underlined] ENGINE CONDTIONS & LIMITATIONS. [/underlined]

[Table showing Engine conditions with associated limitations on R.P.M., Boost, Gear and Time]

[Underlined] Oil temperatures in °C. [/underlined]

Minimum for take-off. 15°C (or increase of 5° if above.)

Max for cruising. 90°C. (100° short period emergency.)

Emergency max. 105°C – Danger point.

[Underlined] Oil pressures in lbs/□” [/underlined]

High pressure 45 – 90.

minimum 30.

Low pressure 6 – 10.

[Page break]

[Underlined] OPERATIONAL CLIMB [/underlined]

[Graph showing throttle revs., airspeed and heights]

Select 2650. + 4. at end of take-off climb to full throttle height when throttle lever will be at the gate. Change to ‘S’ gear leaving throttle at gate & bring revs up to 2850. Boost will rise to +9. Climb at these settings irrespective of drop off in boost above R.A. until 20,000 feet is reached. Fly for sufficient time to use 150 gals (1,000 lbs) or 1hr to lighten plane before continuing climb. I.A.S. 160 mph.

[Underlined] ENDURANCE FLYING [/underlined] 3,000’. & below.

1800 r.p.m. I.A.S. 135m.p.h. Boost? Maintain flying speed & rpm by varying throttle.

[Page break]

[Underlined] MAXIMUM CLIMB [/underlined]

[Graph showing settings in maximum climb at different heights]

Select 2850 +9 after end of initial take off climb. Boost will be maintained automatically up to R.A. (10,000’.) When boost has fallen by 3lbs change to ‘S’ gear. [ word missing] will take control until R.A in ‘S’ gear (17,500’.) from then on boost will gradually fall off.

[Underlined] CRUISING OVER 3,000’. [/underlined]

[Underlined] Ideal conditions, [/underlined] throttle lever at gate, piston forward, butterfly wide open. Cut down rpm to get 160-170 I.A.S.

If revs in [deleted letter] ‘S’ are below 2,300 change to ‘M’.

If revs in ‘M’ are above 2500 change to ‘S’.

Max permissible R.P.M. in ‘M’. above 12,000’ is 2,500.

Never exceed +4lbs boost. Always fly at recommended I.A.S. ‘M’ or ‘S’ 160-170 mph. Always fly at recommended altitude 8,000’ to 16,000’. Fly in cold air whenever possible (intakes.)

[Page break]

9/. Momentarily take throttle through gate. (3,000 +12.)

10/. Throttle back to +9. Check mag drop. Should not exceed 100 rpm.

11/. Throttle back to 0 boost.

12/. Check 2 speed blower – momentary increase in boost & drop in R.P.M. (red light should come on)

13/. Throttle back to 1500 rpm. Snap throttle back to Slow running to check for engine cut out ([underlined] 20 [/underlined]-450 to 650) (28-600-800.)

14/. Advance throttles slightly to clear engine.

15/. I.C.O to OFF position.

16/. Mags off as prop stops turning, petrol off & I.C.O to on-position.

[Deleted] [Underlined] STARTING UP. [/underlined]

1/. Check position of cross-balance cock, note freedom of movement.

2/. Ground – Flight switch to flight.

3/. U/C locked down, bomb doors closed, flaps neutral.

4/. U/C indicator & flap indicator ‘ON’. [/deleted]

[Underlined] STARTING UP. [/underlined]

1/. Cross balance cock [underlined] OFF. [/underlined]

2/. G/F switch to [underlined] Flight. [/underlined]

3/. Switch on Engineers [sic] panel. [underlined] ON. [/underlined] Check fuel contents & warning lights (if fitted.) Select tanks & switch on booster pumps (No 2.)

4/. U/C lever [underlined] locked down [/underlined]. Bomb doors [underlined] closed [/underlined], flaps [underlined] neutral [/underlined].

5/. U/C & flap indicators [underlined] ON. [/underlined]

6/. Brake pressure min: of [underlined] 150lbs. [/underlined]

7/. Boost out out [sic] [underlined] up (not pulled.) [/underlined].

8/. S/Ch in [underlined] ‘M’ Gear. [/underlined]

9/. Air intakes [underlined] cold [/underlined].

10/. Throttles [underlined] 3/4" open [/underlined].

11/. Props [underlined] max. R.P.M [/underlined].

12/. Ground Flight switch to [underlined] Ground. [/underlined]

13/. I.C.O to [underlined] I.C.OFF position. [/underlined]

14/. Master fuel cocks [underlined] ON. [/underlined]

15/. Ignition & Booster coil [underlined] ON. [/underlined]

16/. Contact ground crew (External acc & priming.)

17/. Press starter button & Put [sic] I.C.O [underlined] ON [/underlined] as engine fires. (OFF again if engine fails to pick up. [sic]

[Page break]

[Underlined] SUPERCHARGER [/underlined]

S/Ch fitted to give extra power at sea level & maintain sea level power at altitudes. Centrifugal impellor [sic] driven from rear of crankshaft. It contains one upper centrifugally loaded clutch for m. gear & two lower pack clutch gears for ‘S’ gear. Clutches allow gear changing & absorb high loads during acceleration. Cam shaft turned by piston, operated by scavenge oil, changes gears by means of forked rods. [deleted] Sevo [/deleted] Servo piston is controlled by a rotary valve, which is in turn operated by a pneumatic jack which is electrically controlled.

[Underlined] Boost Regulator maintenance. [/underlined]

Every 50 hours – (minor inspection) a teaspoonful of Anti freeze type ‘A’ oil to lubricate landed valve & sleeve.

[Underlined] Economical Climb [/underlined]. Booster pumps off at 2000’.

I.A.S. 160 – 170. Boost +4. R.P.M. will vary with altitude of aircraft. Above 10,000’ boost will have to be maintained by manual opening of throttle. Change into ‘S’ gear when boost falls by 2 lbs below that desired. Booster pumps on at 17,000’.

[Underlined] DISPERSAL DRILL [/underlined]

[Underlined] PRE-STARTING. [/underlined]

[Numerical points obscured]

Chocks in position, Pitot head, Static vents, Cockpit, turret & wheel covers off cable cutter covers. Jury struts.

Visual inspection of hinged leading edge, engine cowlings, tyres for creep, cuts, etc: & rudder hinges. Oleo leg extensions.

Check state of fuel tanks from Form 700.

Enter A/C & check.

[Numerical points iobscured]

[Underlined] Axes [/underlined], First aid kit, external dingy [sic] release, dip sticks, D.R. Compass for freedom of movement.

Fire extinguishers. Portable oxygen bottles.

Pyrotechnics – flame floats & equipment properly stowed.

Security of hatches.

Oxygen main cock [underlined] ON [/underlined].

Emergency air. 1200lbs/□”.

Initial hydraulic acc pressure.

G/F switched to Flight.

Cross feed cock. off.

Check fuel contents gauges & booster pumps with ammeter.

Select No 2 tanks

[Page break]

12/. Test trimmers for freedom of movement.

13/. U/C locked down.

[Underlined] Pilot & Engineer. [/underlined]

1/. Brakes ON note pressure.

2/. Bomb doors closed.

3/. Mixer box to I/C position.

4/. Auto control clutches IN.

5/. Flap gauge & U/C indicator lights ON.

6/. Altimeter to zero.

7/. Flap lever in Neutral.

8/. Air intakes to cold.

9/. R.P.M. Levers to max.

10/. S/Ch to ‘M’.

11/. Master switch to Ground.

12/. Booster pumps ON.

13/. Contact ground crew.

14/. I.C.O. to off, master fuel cock ON. Ignition & booster coil on.

15/. As engine fires switch on I.C.O. Booster coil off. Oil pressure.

16/. Warm up 1200 to 1500 rpm.

17/. Check mags for dead cut. [Underlined] SEE BACK. [/underlined]

[Underlined] Cut-out [/underlined] used for take-off if load exceeds 61.500 lb A.U.W. if this is to be used it should be checked on run up. Put cut-out at slow running & open up to gate just long enough to note boost.

Captain of air-craft calls up each member of A/C in turn to check equipment.

[Underlined] Taxying [/underlined], follow ground crews [sic] signals, Engineer watches Stbd: side of track. Rear gunner watches for overtaking aircraft. Test brakes. [Underlined] Never [/underlined] turn with a wheel locked.

Keep inboards at 1000 (approx.) rpm & use outers to turn etc:

Use brakes as little as possible with safety.

[Underlined] Take Off. [/underlined]

Pilot gives order – pause & carry out.

1/. Engines opened up to clear.

2/. Opened up to T.O.B. on “Ready for take off”. After check temps etc:

3/.

4/.

5/. 100’ U/C up.

6/. 1,000’ return cut out & Select +9, 2850 r.p.m.

[Page break]

7/. Flaps up slowly as possible while Pilot re-trims.

8/. Select climbing R.P.M. & Boost.

9/. 2,000’ booster pumps off.

10/. 4,000’ oxygen on (night only).

[Table of Pilot and Engineer intercoms and actions for take off]

[Underlined] ECONOMICAL CLIMB [/underlined]

[Graph of heights, throttle settings, boost & rpm]

Select 2650r.p.m & +4 boost when Pilot asks for climbing power. This will be controlled by regulator up to R. ALT (10,000’.) above this it is maintained by manually opening throttle until lever is at gate. When boost then falls by 2 lbs, change into [deleted] s [/deleted] ‘S’ gear. & continue to control manually at +4 up to F.T.H in ‘S’.

[Page break]

[Underlined] LOW LEVEL CRUISING [/underlined]

Reduce R.P.M to 2650.

Select +4 boost.

Select 1800 r.p.m.

Never use more than + 4 boost. If Boost tends to rise throttle back. [Underlined] Ignore I.A.S. [/underlined]

[Underlined] Target area [/underlined]

Select tanks containing most fuel. Switch on 4 main booster pumps. Continue cruising conditions.

[Underlined] Return [/underlined] ???([underlined] 3 or 4 engines. [/underlined])

Trim to desired angle of descent (Pilot.)

Boost below + 4.

160 I.A.S.

Control I.A.S. by r.p.m.

2,300 in ‘S’ [deleted letters] raise to 2,500, change to ‘M’.

When 1800 r.p.m is reached I.A.S will rise – carry on.

Below 3,000’ keep boost below + 4 with throttle ignore I.A.S.

[Underlined] Descent. (2 engines.) [/underlined] ??!!!!*√∏*

Will maintain height of below 10,000 ft

R.P.M. 2850. Boost + 9. I.A.S. ? Change ‘M’ 12,000ft.

If height is lost with +9 in ‘M’ pull cut out.

[Underlined] Landing [/underlined]

[Inserted] Auto control “out”. Clutch “out”. [/inserted]

Pre landing check. S/Ch in ‘M’. Air intakes cold. Brake Pressure 150 lbs/□” (minimum). Booster pumps [underlined] on [/underlined]. Select tanks with most fuel.

[Diagram of approach to landing showing flaps, rpm, speed and undercarriage instructions.]

[Page break]

[Underlined] AFTER LANDING [/underlined]

Select flaps up.

Open rad: flaps.

Check brake pressure.

Couple up Aldis lamp if required.

At dispersal check mags & S/Ch blower.

I.C.O off mags off. Master & Selector cocks off.

Switch off electrical services & G/F switch to “flight”.

Select flaps down.

Return I.C.O. to [underlined] ON [/underlined]. Rad: flaps to auto.

[Underlined] DE [inserted letter] S [/inserted letter] CENT. [/underlined]

[Diagram showing angle of descent with booster instructions, I.A.S. and R.P.M. instructions.

[Page break]

[Underlined] Clark’s viscosity valve [/underlined].

Allows rapid warming up of oil by means of bye-passing [sic] the oil cooler until oil has reached a temperature which allows free lubrication of engine & then controls minimum temperature of oil.

[Underlined] Overheating of oil [/underlined]. Blocked impact tubes. Blocked radiator. Shortage of oil.

[Underlined] Loss of oil pressure. [/underlined] – No oil, gauge U/S, damaged capillary. Shared pump drive.

[Underlined] Low oil pressure. [/underlined] – Worn bearings (main or big end.) Faulty gauge. Dirt under relief valve. Dirty filter. Leaky pipes. Damaged or worn pump gears.

[Underlined] Fluctuating pressure [/underlined]. Air bleeding in suction side of pump.

[Underlined] Dry Sump system [/underlined] 1. Pressure & 2. Scavenge pumps. Scavenge pumps have 20% greater capacity than pressure pumps to maintain a dry sump.

Oil flows from tank to pressure pump.

From 4 crankcase web into gallery pipe & so crankshaft bearings & forward to c.s.v & Pesco pump.

Branch line from pump lubricates fuel pump [inserted] seal [/inserted] & on S.I. engine, the Heywood compressor also.

[Underlined] Low pressure [/underlined] – through external pipe to reduction gear. Also rearward to cam shaft, S/C rear bearing, S/C gears. etc: Fuel, oil & water pump lubricated by the fluid they carry. Linkwork at rear hand lubricated.

[Underlined] Lower spindle of coolant pump [/underlined] is greased by groove cup. (Silcaline grease.)

Scavenge system taken from sump through filters to S/Ch gear change (if ‘20’ to carb butterflies) then to viscosity valve back to tank.

[Underlined] Coolant System [/underlined]

[Underlined] Glycol [/underlined] to reduce freezing point. (-14°C.) Water is best coolant.

[Underlined] Drain [/underlined] at base of pump & radiator screws.

[Underlined] Capacity [/underlined] approx 12 gallons.

[Underlined] Thermostat [/underlined] at outlet of header tank. Allows coolant to warm up quickly & controls the minimum temperature. Coolant passes through radiator from 85° all coolant goes through at 105°.

[Underlined] Radiator [/underlined] pressure tested to 30 lbs/□”.

[Page break]

[Underlined] Cabin heating [/underlined]. From ‘B’ block return to inlet side of pump.

[Underlined] Carburettor [/underlined] jacket from ‘A’ block return to inlet side of pump.

[Underlined] Circulation [/underlined] – Header tank, thermostat, (radiator or bye [sic] pass)

Pump, - inlet rails, through blocks to outlet rails, back to header tank.

[Underlined] Pressure system, [/underlined] if punctured temperature of coolant will fall to boiling point for that height. When coolant becomes short, temp: will remain the same but oil temp: will rise. Pressure is caused by heat generated in system & allows running temperatures of over 100°C. Pressure is maintained by [underlined] Teddington thermostatic [/underlined] relief valve. Blows off at max: of 30 lbs. Allows air to pass in at 2 1/2 lbs below in atmospheric pressure. Keeps pressure sufficient to stop boiling.

[Underlined] Temp: gauge [/underlined] connection & connection to thermostatic rad: shutter control at outlet of header tank.

[Underlined] Rad: flaps [/underlined] open 105°C, close 99°C.

[Underlined] Thermostat [deleted] ic [/deleted] [/underlined] becomes operative & starts to pass coolant through radiator at 85°C & all coolant passes through rad at 105°C.

[Underlined] S.U. Carb: [/underlined] A.V.T. 40/

[Underlined] Setting of needles [/underlined] should be checked against measurements and conditions laid down in A.Ps. (AP1590. G. VOL I.)

[Underlined] Slow running [/underlined]. Fuel from main jet taken up S.R. tube air is bled into top of tube to emulsify fuel and out to edge of butterflies (when nearly closed) via S.R. box.

R.P.M. 456 – 600.

[Underlined] Diffusors [/underlined] each has a disc jet at its base though which fuel must flow. It is regulated here by needle valves. Air is admitted to top of diffuser at intake pressure & forms an emulsion which passes via the main delivery to the choke.

[Underlined] Accelerator pump [/underlined] used to overcome time lag of fuel, in reaching induction when throttle is opened.

[Underlined] Enrichment aneroid [/underlined] does not move until Boost pressure exceeds +4 1/2 lbs, beyond this needle is progressively lifted to give rich mixture.

[Underlined] Altitude mixture control [/underlined]. progressively reduces size of jet to keep mixture strength constant.

[Underlined] Hot coolant [/underlined] is passed round the jacket, & scavenge oil through the butterfies [sic] to prevent icing

[Page break]

[Graph of BHP and Altitude in 1000ft.]

[Page break]

[Graph of MERLIN XX & XXII WEAK MIXTURE CONDITIONS ‘M’ GEAR & ‘S’ GEAR with B.H.P. and Altitude in 1000ft.]

[Page break]

[Calculations]

[Page break]

Fuel system 150.

Engine General 50.

Carburettor & Propellor 100.

Engine ground testing 50.

Engine air handling 150.

Log keeping 50.

Airframe general 50.

Jettisoning, ditching, dingies [sic] 100.

Hydraulics, Pneumatics, Electrics 100.

Anti icing, Oxygen, F.Es . inspection of A/C. 100.

Manufacturers [sic] course 50.

Fuel calculation (consumption.) 50.

Total 4,000.

Collection

Citation

Syd Marshall, “Flight engineer's training notes for a Lancaster,” IBCC Digital Archive, accessed July 22, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/2555.

Item Relations

This item has no relations.