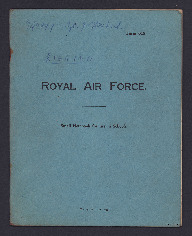

John Hitchcock's Rigging Notes

Title

John Hitchcock's Rigging Notes

Description

Notes kept by John during his training.

Creator

Coverage

Language

Format

One booklet

Conforms To

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Identifier

MHitchcockJS740899-170926-24

Collection

Citation

John Hitchcock, “John Hitchcock's Rigging Notes,” IBCC Digital Archive, accessed July 30, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/36990.

Item Relations

This item has no relations.