Engine handling notes - Lancaster III

Title

Engine handling notes - Lancaster III

Description

Starting procedure, testing engines and installations, drill before taxying and post taxi drill,

Language

Format

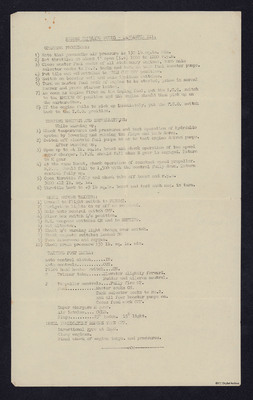

One page typewritten document

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Contributor

Identifier

MWareingR86325-161005-70

Transcription

[underlined] ENGINE HANDLING NOTES – LANCASTER III. [/underlined]

STARTING PROCEDURE:

1) Note that pneumatic air pressure is 130 lb. sq.in. min.

2) Set throttles at about 1” open (i.e.) 1000 to 1200 r.p.m.

3) Close master fuel cocks of all stationary engines, turn main selector cocks to No. 2 tanks and turn on tank fuel booster pumps.

4) Put idle cut off switches to IDLE CUT OFF position.

5) Switch on booster coil and main ignition switches.

6) Turn on master fuel cock of engine to be started, prime in normal manner and press starter button.

7) As soon as engine fires on the doping fuel, put the I.C.O. switch to the ENGINE ON position and the engine should then pick up on the carburetter.

8) If the engine fails to pick up immediately, put the I.C.O. switch back on to the I.C.O. position.

TESTING ENGINES AND INSTALLATIONS:

While warming up,

1) Check temperatures and pressures and test operation of hydraulic system by lowering and raising the flaps and bomb doors.

2) Switch off electric fuel pumps so as to test engine driven pumps.

After warming up,

3) Open up to +4 lb. sq. in. boost and check operation of two speed super charger. R.P.M. should fall when S gear is engaged. Return to M gear

4) At the same boost, check operation of constant speed propellor. R.P.M. should fall to 1,500 with the control fully down. Return control fully up.

5) Open throttle fully and check take off boost and r.p.m. 3000 +12 lb. sq. in.

6) Throttle back to +9 lb sq.in. boost and test each mag. In turn.

DRILL BEFORE TAXYING:

1) Ground to flight switch to FLIGHT.

2) Navigation lights on or off as required.

3) Main auto control switch OFF.

4) Mixer box switch i/c position.

5) D.R. compass switches ON and to SETTING.

6) Set almeter.

7) Check u/c warning light change over switch.

8) Check magneto switches locked ON

9) Test inter-com and oxygen.

10) Check brake pressure 130 lb. sq. in. min.

TAXYING POST DRILL:

Auto control clutch …… IN.

Auto controls ……………. OUT.

Pilot head heater switch …. ON.

T Trimmer tabs …… Elevator slightly forward.

Rudder and aileron neutral.

P Propellor controls …. Fully fire UP.

Fuel ………………… Master cocks ON.

Tank selector cocks to No. 2.

and all four booster pumps on.

Cross feed cock OFF.

Super chargers M gear.

Air intakes …. COLD.

Flaps ………….. 25[degrees] laden. 15[degrees] light.

DRILL IMMEDIATELY BEFORE TAKE OFF.

Directional gyro at ZERO.

Clear engines.

Final check of engine temps. And pressures.

STARTING PROCEDURE:

1) Note that pneumatic air pressure is 130 lb. sq.in. min.

2) Set throttles at about 1” open (i.e.) 1000 to 1200 r.p.m.

3) Close master fuel cocks of all stationary engines, turn main selector cocks to No. 2 tanks and turn on tank fuel booster pumps.

4) Put idle cut off switches to IDLE CUT OFF position.

5) Switch on booster coil and main ignition switches.

6) Turn on master fuel cock of engine to be started, prime in normal manner and press starter button.

7) As soon as engine fires on the doping fuel, put the I.C.O. switch to the ENGINE ON position and the engine should then pick up on the carburetter.

8) If the engine fails to pick up immediately, put the I.C.O. switch back on to the I.C.O. position.

TESTING ENGINES AND INSTALLATIONS:

While warming up,

1) Check temperatures and pressures and test operation of hydraulic system by lowering and raising the flaps and bomb doors.

2) Switch off electric fuel pumps so as to test engine driven pumps.

After warming up,

3) Open up to +4 lb. sq. in. boost and check operation of two speed super charger. R.P.M. should fall when S gear is engaged. Return to M gear

4) At the same boost, check operation of constant speed propellor. R.P.M. should fall to 1,500 with the control fully down. Return control fully up.

5) Open throttle fully and check take off boost and r.p.m. 3000 +12 lb. sq. in.

6) Throttle back to +9 lb sq.in. boost and test each mag. In turn.

DRILL BEFORE TAXYING:

1) Ground to flight switch to FLIGHT.

2) Navigation lights on or off as required.

3) Main auto control switch OFF.

4) Mixer box switch i/c position.

5) D.R. compass switches ON and to SETTING.

6) Set almeter.

7) Check u/c warning light change over switch.

8) Check magneto switches locked ON

9) Test inter-com and oxygen.

10) Check brake pressure 130 lb. sq. in. min.

TAXYING POST DRILL:

Auto control clutch …… IN.

Auto controls ……………. OUT.

Pilot head heater switch …. ON.

T Trimmer tabs …… Elevator slightly forward.

Rudder and aileron neutral.

P Propellor controls …. Fully fire UP.

Fuel ………………… Master cocks ON.

Tank selector cocks to No. 2.

and all four booster pumps on.

Cross feed cock OFF.

Super chargers M gear.

Air intakes …. COLD.

Flaps ………….. 25[degrees] laden. 15[degrees] light.

DRILL IMMEDIATELY BEFORE TAKE OFF.

Directional gyro at ZERO.

Clear engines.

Final check of engine temps. And pressures.

Collection

Citation

“Engine handling notes - Lancaster III,” IBCC Digital Archive, accessed November 2, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/28316.

Item Relations

This item has no relations.