Gunnery School Notes

Title

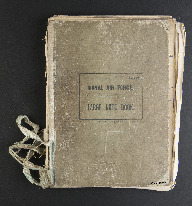

Gunnery School Notes

Description

A book used by Colin McDermott to record his notes from Gunnery school. Subjects covered include the Browning and Vickers guns, gun sights and their use, turrets, range standing orders and the Boulton Paul turret.

Creator

Language

Type

Format

One notebook with 136 pages of handwritten notes

Conforms To

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Identifier

MMcDermottC1119618-161216-11

Collection

Citation

Colin McDermott, “Gunnery School Notes,” IBCC Digital Archive, accessed July 22, 2024, https://ibccdigitalarchive.lincoln.ac.uk/omeka/collections/document/27353.

Item Relations

This item has no relations.