Elizabeth Humphrey's training notebook

Title

Elizabeth Humphrey's training notebook

Description

A notebook used by Elizabeth Humphrey during her training as an instrument technician.

Creator

Coverage

Language

Format

123 handwritten pages

Publisher

Rights

This content is available under a CC BY-NC 4.0 International license (Creative Commons Attribution-NonCommercial 4.0). It has been published ‘as is’ and may contain inaccuracies or culturally inappropriate references that do not necessarily reflect the official policy or position of the University of Lincoln or the International Bomber Command Centre. For more information, visit https://creativecommons.org/licenses/by-nc/4.0/ and https://ibccdigitalarchive.lincoln.ac.uk/omeka/legal.

Identifier

SHumphreyE2098310v10006

Transcription

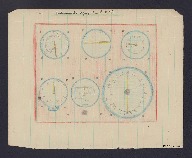

[underlined] Instrument Flying Panel MK.I. [/underlined]

[drawing of an instrument panel]

[page break]

[underlined] Boat Gauge. [/underlined]

Red bezel.

Choke and filter in union at back.

[annotated drawing of a boat gauge]

[page break]

[annotated drawing of an aircraft]

[page break]

[underlined] Ratio of presacion [sic] [/underlined] – increased motor speed decreased rate of preseacion [sic] vica

I ncreased [sic] [deleted] torque [/deleted] increased rate of preacion [sic],

[underlined] Directional Gyro [/underlined]

[annotated drawing of a directional gyro]

MK3C* Boat gauge.

Mechism [sic] separated from the inlet G means of a diagram it is therefore on necessay [sic] to have an airtight bezel as no leak can accur [sic], no drain [inserted] traps one [/inserted] required.

[page break]

[underlined] Directional Gyro. [/underlined]

Purpose. – To indicate to the pilot the attuide [sic] of his A/C in a turn. Lit [sic] is independent of asauloration [sic] error and northerly turning errors it is situated on the B.F.P. and the rotor is driving by means of a pipe from the back of the instrument to the fesgo, [sic]

[underlined] D.I. [/underlined] Check for general security test the caging divce [sic] for freedom baring in a loc [missing text] position check security of filter

[underlined] First. Minor. Inspection. [/underlined]

Remove filter clean glase [sic] in petrol renew time pad and replace.

[underlined] Artifical [sic] Horizon. [/underlined]

To indicate to the pilot the attuide [sic] of the A/C diving climbing & banking whilst flying in conditions of poor visibility,

[underlined] Daily. Inspections [/underlined]

C G. V,D.S. – Check the suction and with engines running the model A/C. should slightly above the horizon bar

First. Minor, Inspection –

[page break]

[underlined] Air.. LAY.OUT. [/underlined]

[annotated drawing of Air Layout]

[page break]

Remove clean and replace filter and renew tisuie [sic] pad.

[underlined] When. fitting Artifical Horizon. [/underlined]

[5 drawings of pitch and level indicators]

[underlined] Check Valve. [/underlined]

[page break]

[underlined] Sperry [sic] Gyro Pilot [/underlined]

purpose: –

1. To maintain the A/C on a true course Level f/aft and latterly level

2. To increase the accurately of ailel [sic] photo.

3. To release the polit of strain, and to increase the safty [sic] factor when flying in conditions of poor visiablity [sic] The gyro polit inplys [sic] a modifed [sic] version of the deniction [sic] gyro ar [sic] Horizoncal [sic] Artfical [sic] as ontrol [sic] units Both units are housed in a mounted unit fitted in front of the pilot where the B.F.A. is usually placed. The D.G. unit controls rudder the Flanking Climb unit control elevator eilrogans [sic].

[underlined] The Air System. [/underlined]

purpose: – fego [sic] pump

This pump is the means of supply the ofratiy [sic] [deleted] il [/deleted] sustion [sic] of 3 to 5 in H.G

[deleted] This p [/deleted]

[underlined] Discriptions [sic] [/underlined]

This pump is directly connected to the engine crank shaft and the inlet union

[page break]

[underlined] Bridge Megger [/underlined]

[annotated picture]

[underlined] Twin. Pointers. MK. II A. [/underlined]

[underlined] Electrical. Engine. Speed. Indicator. [/underlined]

[drawing showing Engine speed in Hundreds of R.P.M.]

[page break]

[underlined] Two Scales. [/underlined]

1 Shows contents in the two positions of A/C

2 Shows “ of tanks of different shapes

[underlined] Selector. Switch [/underlined]

Used so that on gauge can serve more that one tank. (See wiring Diagram)

[page break]

[underlined] Intallation [sic] [/underlined]

Gauge.

Make sure that the rubber band is round the instrument.

2. Put instrument through hole in panel.

3. Place metal ring round instrument and tighten lug [circled number] 1 [/circled number]

4. Turn gauge in panel so that, the pointer in left if zero.

5. Tighten screws in lugs [circled number] 2 [/circled number] against the panel

6. “ lock nuts.

7. Connect cable.

Red to B+

Blue “ B-

Green “ P.

[underlined] Installation (Tank Unit) [/underlined]

1. Fit unit into hole provided making sure cork washer is fitted first.

2. Tighten the 12 nuts (lack with wire)

[underlined] Selector Switch. [/underlined]

1 Fit in panel n place provided.

[page break]

[underlined] Reflector. Gun. Site. [/underlined]

[underlined] Maintenance [/underlined]

1 Clean glass with shamious [sic] leather.

2. Check functioning of ([deleted] ground tent [/deleted]) switch.

A. Day – very bright.

B. Night – dim light – and dimmer switch operating.

C. Off – no light

3. Change unserviceable bulb.

[underlined] Warning. [/underlined]

Make sure the bulb is inserted properly black line on bulb with white line on socket.

[underlined] Simonds Fuel Content Gauge. [/underlined]

This is of a still tube type and its object is to allow a reading to be taken when the A/C in not is a latterly level position it consists of four parts.: –

Tank unit.

Indicator

Switch and limiting resistance

[page break]

The tank unit is a reartangler [sic] tube of duralum [sic] which capped with alloy casting, the casting carries a small plate which gives the information as which tank it belongs to and which [deleted] (it in) (tank it belongs to) [/deleted] direction is which it is to be fitted,

The indicator is a cylindrical in shape and has two scales and one pointer and the range is only 90o

There is an terminal block it the back carring [sic] three terminals MK. I.C.2

[underlined] The Switch. [/underlined]

Is a small black baklight [sic] case with a white push button which is engraved (Press).

[underlined] The Limiting Resistance. [/underlined]

Is used to limit the current in the circuit and consists of a fibre base plate carring [sic] a small resistance which are protected in a black baklight [sic] cover.

[underlined] Installation. [/underlined]

The tank unit should be fitted tanely [sic] vertical in the correct tank when the

[page break]

A/C is in a flying position and the red amo [missing word] de msll plate should be pointing forward, [missing word] the flange of the tank unit should be fitted a cork washer which has been covered with bostick [underlined] The indicator And Switch. [/underlined] will be fitted in the fuel gauge panel and are flushed mountains

(Installed from the back of panel)

[underlined] D.I. [/underlined]

Press switch and see that the gauge indicates the amount of fuel in in the tank, (Check with filter or form 700) C.G.V.B,S,.

30 br & 30*br Includes D.I, plus general check on wiring fuses terminals etc.

[underlined] Electrical Speed Indicates. [/underlined]

[page break]

system has been designed to cut down maintenance to a minimum and among it advantages are the following:–

1. Being AC. The compass is on affected.

2. The indicator is very accurate.

3. There is no comuntor [sic] or brushes to clean.

4. It is very sensitive

Set consists of to parts the generator & indicates connected together by a length of 3 core cable,

[underlined] The generator [/underlined] is revolved by a flex drive and in appearance is simular [sic] to the MK.II generator expert that we have [deleted] th [/deleted] three terminals and thimble connections where as the MKII has two pin plugs ad sockets the terminals are No 1, 2, 3, and the terminal cover has HK, on it at the back a small connection chart

[underlined] The Indicator [/underlined]

Has simular [sic] connections at the back and the dial is circular and is marked of 1 to 10 and has two points the one afixated [sic] through gearing the hands of the clock The terminals on the indicator are numbered 1, 2, 3, and are coloured red, blue, green, in that order for a clockwise direction rotating engine

No 1. On the generator is connected to red on the indicator

[page break]

2. Wire up according to diagram.

[underlined] Daily Inspection – [/underlined]

1 C.G.C.V.D.S.

2. Check functioning by pushing switch.

3. “ that pointer is left a zero.

[underlined] 30* hr. [/underlined]

Check calibration [deleted] common faults. [/deleted]

[underlined] Common. Faults. [/underlined]

1. Mo reading when bottom is pushed.

Accumulator disconnected

“ run down.

[underlined] Fuse blown. [/underlined]

Leads broken (use continuity tester)

Short Circuit (“ Wee. Meggar)

2. Fuge [sic] blows when button is pushed.

Lat for perished insulation [inserted] (wee meggar) [/inserted] [deleted] between tank full and vertical [/deleted]

3. [deleted] (Red Cad broken.) [/deleted] Pointers moves to a position between tank full and vertical.

Red lead broken.

[page break]

4. Pointer moves to a position between tank empty and [deleted] full [/deleted] vertical.

Blue lead broken.

5 Pointers moves to vertical position.

Green lead broken

[underlined] PNote [sic].:– [/underlined]

In the last three faults.: –

1. If the fault accurs [sic] in all pointers of the selector switch then the break is in the lead to the gauge.

2. If the fault is only in one [inserted] tank [/inserted] position then the break is in the lead to the tank.

[underlined] Engine Cylinder Thermometer. [/underlined]

Measures the temperature of the cylinder.

[underlined] Three parts: –

1. The Lat junction plus abestes [sic] covered lead

2 Compensating leads

3. Indicator.

Hot junctions [deleted] to [/deleted] connected to cylinder lead (1.75 ohms resistance.

[page break]

[underlined] Compensating Leads. [/underlined]

A. Leads (1 only) each lead =1.75 ohms.

10, 20, 30, 40, 50, 60, 70, 80, 90, 100ft.

B. Leads (2 must be used) each lead = .875 ohms

10, 20, 30, 40, 50ft.

C. Leads (3 must be used) each lead = 583 ohms.

10, 20, 30ft.

“ must not be cut or altered,

[underlined] Installation Of Indicator. [/underlined]

Secure it in the panel (join up Condon wire)

2. Remove damping wire, and leave an open circuit

3. After half an hr, compare with master therm,

4. Adjint [sic] pointer by screw in front of indicator

5. Connect compensating lead.

[underlined] Maintenance. [/underlined]

P.I. C.G.V.D.S, Instrument should read temperature of cockpit if engine has not been run up recently check security of leads.

[underlined] 30 Hr. [/underlined]

Check functioning during a ground test of engines.

[page break]

[underlined] Electrically Heated Pressure Head. [/underlined]

D.I. Switched on, Feel the lead to see whether it is heating, if not,

A. Check [deleted] acculion [/deleted] accumulator connectioning [sic].

B. “ “ charge.

C “ fuse.

D “ leads for continuity (i.e. connections etc.)

E “ “ “ short circuit.

If none of these, pressure lead is u/s.

1 When pressure lead is dry and cold any reading less than 3 oneg ohms is unsatisfactory.

2. If pressure lead is sodden, switch on, dry then test when cool.

[underlined] Flap Indicator. [/underlined]

Similar in operation to fuel content gauge.

[underlined] Note. [/underlined]

1 It is continuous in operation.

2. “ reads degrees.

3. It tells the pilot the position of the flaps.

[page break]

to the blue and 3 to the green.

For an anti – clockwise engine blue and green are reversed.

[underlined] Installation. [/underlined]

The generator is fitted on a little bracket near the auxiliary gear box and there is usually is a small sponge pad between the base of the generator and bracket

The Indicator.

In a flush [deleted] mounting [/deleted] fitting on the instrument

[underlined] D.I. [/underlined]

On a engine run up see that the pointer move smoothly C.G.V.D.S,

30 hr & 30* hr.

Same as DI only plus check on the wiring.

[underlined] Design System. [/underlined]

The design of this system has been arranged, so that the different function of the A/C can be measured in the same way

[page break]

These functions include.

Fuel contents, Oil contents

Flap Position, Steering Indicator & Directional Trim.

The advantages of such a system include, accuracy, lightness, space saving, easy maintenance, easy installation and interchangeability.

The principle involved is that of the rotaty [sic] convertor, There are two main pats the transmitter and indicator.

[underlined] Example. [/underlined]

Electrical Fuel Content Gauge II

The transmitter

Is similar to a MKII in that it has a Cahlize [sic] cork [deleted] washer [/deleted] float and gearing.

The main difference between the two is that the MK.II has three pin plugs and sockets and the MKIII has five terminals MK. 1, 2 3, & 6, – 7,

[underlined] The indicator [/underlined]

Is a small cylindrical Lahitie [sic] case with a square front. The pointer is the off position is always vertical and is known as the full off position, The range of the pointer is to approx. 300o at the back of the case.

[page break]

[underlined] D.I. [/underlined]

Switch on dynamotor and see that it works.

Check all visual indicators,

Oil pressure – zero.

“ temperature – days temperature.

fuel pressure – zero

Air intake temperature – dry temperature.

Nose, part, Stld, wheels down, flaps up.

Boat gauge will read the pressure of the day.

in ins of mercury or in millions – 100.

Fuel contents amount of fuel in tanks.

C.G.V.D,S. and switch off.

[underlined] 30br and 30*br [/underlined]

See local U,M,O.s

[underlined] Avometer or Int meter type D. [/underlined]

Setting the Avometer to measure volts and amp A.C.

1. Set the A..C switch to D.C.

2. “ “ D.C. “ “ the required range.

(This may include the setting of the souliplian [sic] knob)

3. Connect the positive terminal to the positive of the supply ad negative to the negative and read of the scale.

[page break]

Note

When measuring volts the instrument must be in parallel and when measuring amps, must be in series.

To Measure Resistances,

1 Set the A.C. switch to D.C.

2. “ “ D C. “ to 10,000 ohms

3 “ “ multiplier knob to K = 2.

4 Connect the positive and negative leads together.

5. Set pointer to zero by means of P switch.

6. Reset the D.C switch to 1,000 ohms and adjust the pointer to zero by means of A switch.

7. Reset the D.C. switch to 10,000 and check zero position

8. Disconnect the 2 leads and carry out test.

Autosyn [sic] System.

This is purely a transmitting system which functions on similar lines to telegon [sic] equipment but has the further advantage of reducing maintenance and weight, There are two main parts the indicator and transmitter.

The transmitters

Are fitted at the particular

[page break]

Telegon [sic] Inter.

[table for 4 dial instruments]

[table for single Indicators and all transmitters]

[page break]

position from which they are to measure,

the engine indicators are fitted on anti – vibrational mounted panel in the engine, So that only start lengths if taking and capillary are required.

The pressure temperature or mechanical movement of the various systems operates a small autosyn [sic] motor which delivers on autopat [sic] if 26 – 52 volts, it 400 – 800 cycles per sec,. This autpat [sic] is collected by an similar motor which moves to line up with the transmitter motor, and in doing 40 mins a pointer over the scale,

Calibrated in lbs pr sq inch degrees centigrade or degrees notation

Recognition

All the transmitters have one motor and are recognised y the case which has a erochlid [sic] black finish. It also bears a small plate in which is inscribed “A/C. US Army transmitter” = eg Fuel pressure. They will carry two unions

1 A tube (aeroquip) or a capillary or a flex drive the other unions.

[page break]

2. Is an electrical plug and socket having four pins marked A,B,C,D,

Indicators (Single)

These are encased with a cover having a crinkled black finish, they have 4 pin plugs and sockets at the rear and carry one pointer and are usually only found in use as flap or bomb door indicators

Dual Indicators.

Carry two motors and are therefore longer, they have 7 pin plugs and sockets at the rear MK, A.B.C.D,E,F,G,

The carry has a crinkled black finish and the dial has two pointers moving over it the pointers are M.K. L & A. or 1 & 2. or 3 & 4 lz [sic] indicator Pat. Stbd engines, The hole system is energised Ga dynameter or an engine driven alternator,

Maintenance D.I. 30 & 30*br } As for telegons

[page break]

Breeze Wire

The prim reason for this type of wire is that the larger A/C can be made in sections already wired. When the sections are connected together by an system of multiple plugs & sockets the A/C is fully wired throughout. It consists of lengths of cable in a metal sheaf and the ends are connected to the plugs & sockets. Each plug and socket is No, so that there can be no confusion when connecting up.

Further advantages include.

1. Complete screening against radio interference

2. Complete bonding.

3. The wires have mechanical support.

4 They are easy maintained and tested

5 In A/C operating near the sea, the wiring is absolutely [deleted] waluff [/deleted] waterproof.

[page break]

Oxygen

Uses

Oxygen is used in A/C to supply the members of the crew with sufficient i- [deleted] to [/deleted] to maintain there normal activities without oxygen the nervous system becomes affected, muscular reactions are slow and a times there is complete loss of vision. This state is known as “Black out”

Oxygen is used under the following conditions

1 When the duration of flight at 10,000f exceeds 1 hour.

2. All heights above 15,000ft.

3. Whenever it is cold.

4. When the rate of climb exceeds 2,000 ft pr min,

Oxygen is stored in sribel [sic] steel cylinders of seamless construction. They hold 750 leters 1,800 lbs pr sq ins. They are two types thou [sic] used in normal systems and those used in, insitor [sic] The Normal Bottle. has pointed on it, “After removal from AC remaining contains not to be “discharged”.

Around the neck of the cylinders is a brass collar on which is stamped the MK.

[page break]

and the date of issue into the service.

Screwed into the neck is a cylinder valve (MK VII) which must be fully [underlined] open [/underlined] or fully [underlined] closed. [/underlined] The handle of the valve is MK. “use on oil or grease”

The only difference between normal and insitu cylinders is that the insitu cylinder has a double layer of steel wire, to prevent fragmentation and the cylinder valve is replaced by a 3 way connecting piece.

When Cylinders Should Be Returned To Stores.

Two years after the date stamped on the collar,

2. When cylinder are accidently empty

3. “ all the paint has being scuffed off.

“ the oxygen has a bad smell

Connections

Cylinders are arranged in batched and connected into a main pipe lie by 3/16” 16 gauge high pressure copper tubing, with nipple connections

These lengths of tubing are arranged in loaf of 8” in diameter to allow

[page break]

[annotated drawings of cylinder wiring]

[page break]

[annotated drawing of OXYGEN INSALLATION [sic]]

[page break]

1. Black steel casing

2. Squared shaft 1” at engine end 1/2” at generator end

3. Split washer at short end only

4. Casing cover small at same end to permit shaft to [deleted] permit [/deleted] pass through

5. Engine end has grease hole.

[underlined] Installation. [/underlined]

1. Make sure electrical connections are correct

2. If not remove the screw in the plug and reserve the pins.

3. Generator bolted on or near the engine

4. Indicator is supported in the panel by a bracket

5. Flexible drive must be cleated with no sharp bends.

6. Gear box should be greased with high melting point grease.

7. Grease drive with anti-freezing grease.

[underlined] Maintenance. [/underlined]

DI – C.G. C.V.D.S. – check functioning when engines are run up.

*hr –

Remove and clean brushes, clean [inserted] commuters [/inserted] if necessary

[page break]

check the calibration.

[underlined] Flauts. [sic] [/underlined]

1 No Reading – Plug reversed, broken leads, short circuit

2. Flickering pointer – Faulty flexile drive

“ brushes.

“ Commutors

Broken coil in armature

Bad connections

3. Under Reading – Oil or grease in commuter

Fuel Contests Gauge.

[underlined] Tank Unit. [/underlined]

Position of the float depends upon the amount of petrol, Three wires (tri – oil) cable, red, blue, green wire to connect arm

[underlined] Gauge. [/underlined]

Reads only when button is pushed (to prevent risk of fire) Three connections

B+ Red lead

“- Blue “

P Green “

Pointer is to the left of zero when no reading is being taken

[page break]

static) take to prevent [deleted] (to by [/deleted] the ingress of dust and moisture. Later types of pressure lead have the pressure and static tubes concentrically arranged, and electrically heated. The electrical element should never be left switch on for more than 5 mins, when the A/C is on the ground.

[underlined] Installation. [/underlined]

The A.S.I is installed in the instrument panel and connected to the pressure head by 5/16” O D. alum, tubing and MK I low pressure union. The joints should be as few as possible, and the pipe line should have no loops which may collect water, Pipe lines being installed should be dated at each connection made. A/C with with [sic] folding are fitted with M.K. I. flexible connection near the hinge A.P. 1275 VOL I Sect. I . Chap. III fig. 19.

In cases where a continuous fill in the pipe line from the instruments to the pressure lead cannot be obtained, a drain trap must be fitted in the lowest part of the pipe line.

The trap consists of a 4” length of 3/16” O.D copper tubing into each pipe line by means of a low-pressure “T” union.

[page break]

[underlined] Maintenance [/underlined]

D.I. Insure that the glass is clean and the instrument is secure. Where an electrical heater is fitted its function correctly.

[underlined] 30. br inspection [/underlined] – Check the pressure head for security, ensuring that the trap and static holes are clear and free from burns.

Drain A.S.I drain traps.

[underlined] 30*br D.I. [/underlined] Test both pressure and static pipe – lines for leaks.

[underlined] Turning Indicator. [/underlined]

This instrument is fitted in the B.F.P. and gives the pilot two indicatings

1. The rate at which the A/C is turning

2. Wether [sic] the A/C is correctly lanled [sic] or not

The dial consists of two halves, the lower half has a scale MK 1.2.3.4. on both side of a centre zero, moving over the scale is a pointer which is controled [sic] by a gypocqas [sic] the A/C turns the gyroscope is dupliced [sic and moves to indicate by tb [sic] pointer the direct in which the A/C [deleted] (th) [/deleted] is turning and at what rate, The figure 1, represents 170o pr mins fig.2. 360o pr min. fig.3. 660o pr min, fig 4 1080 pr min

[page break]

the top pointer is controled [sic] by a pendulous weight and moves over a scale of degrees, again M.K. on both sides of centre zero. The pendulous weight is affected by gravity and centrifugal force.,

In a correct bank these two forces are equal and the pointer remains on zero, if the A/C is not correctly banked the pointer indicates by how much and which direction the A/C is [deleted] std [/deleted] sidretepng [sic]. The instrument carries a connection for connecting to the suction pipe, the air drawn from the case camus [sic] the air in the A/C to enter the case aria filter and jit [sic] the air impurges [sic] in the rota buckets and the rota is turned at speed,

The instrument must be installed with both pointers at zero when the A/C is literly [sic] level.

[underlined] D.I. [/underlined] C.G.V.D x S. and see that top pointer indicates the lateral position of the A/C and the bottom pointer reads zero.

[underlined] 30* br. [/underlined] – Clean filter and check calibricity [sic]

[underlined] N.B. [/underlined] Filters are removed in the case of the MK I. by unscrewing a small cap over the air inlet and in the case of the read sigreat [sic] type by removing the back pl

[page break]

a fig spanner.

A.S.I. Leak Tester – The static connection applies a suction till the instrument reads 180 mls pr hr seal of and the pointer should not drop more than 15 mls pr h in 10 seconds.

Applie [sic] a pressure to read 150 mls pr hr seal of and there should be no leak.

Disconnection the pipe line from the pressure lead and “T” in a standard A.S.I. applie [sic] a pressure till the instrument reads 15.0 and tince [sic] taken to drop to 135 mph should not be less than 1/2 x L/16 (N + L/16) seconds where N. equals the No of instruments and L. equals length of tubing, Applie [sic] a suction to the instrument reads 150 mls and the pointer should not drop below 135 in less than 5/8Y. seconds

[page break]

[underlined] The MK. I. Barometer (Portable) [/underlined]

This instrument measures by a column of mercury atmospheric pressure and is used when calibrating and checking air-craft instruments when being used certain conditions must be taking into acount [sic] i.e. gravity temperature and isothermal or T.C.A.N. laws to read it move the cursor until the two knife edges and the memisue [sic] of the mercury are in line and read of on the contracted ins” scale the position of the datum MK on the front of the cursor

It should be installed on a flat sturdy base out of drafts and the direct rays of the sun.

[underlined] MK XIII [/underlined]

The mechanism is enclosed in a black bak-light case with a nipple at rear for connection into the static pipe line so that the instrument will read the boran [sic] pressure in turns of high the dail [sic] has to calibration circles and one pointer, the dail [sic] is moved by a small knob at the bottom right hand side of the case there is a hole in the dail [sic] which carries two datum MKs and there is a third on

[page break]

Second dail [sic] beneath the top dail, [sic]

When the pressure is standard the two datum marks when not against the third should bring the zero beneath the pointer is the day is not standard when the datums are sit the pointer will read the amount where on below standard in feet

[underlined] Leak Test. [/underlined]

Before fitting in crew position applie [sic] a leak test.

[underlined] MK. XIV. Altimeter [/underlined]

It is fitted in a long bak-light case the mechanism is fitted inside it the case carries a nipple at the rear for connections into the static pipe line, the dail [sic] is marked 1” to 10” end there re three pointer a large one measures in hundred a smaller one measuring in thousands and even smaller one measured is 10, of thousands The dail [sic] carries a small window thought which can be seen a milibar [sic] scale the bottom of the case carries a small knob and when this is

[page break]

turned the pointers and the milibar [sic] scale [underlined] both [/underlined] moves when the air-craft [underlined] only [/underlined] the pointers move. This scale has been provided for three reasons. [deleted] (when the) [/deleted]

1/ When the scale is set to the days pressure the pointers should be at zero.

2/ If the pointers are set to read the high of the [deleted] (high of the) [/deleted] aerodrome above sea level the milibar [sic] scale will read the barometric pressure at sea level at that time

3/ If the pilot is found tot land at some aerodrome other than his own he can set the new barometric pressure and when he lands the pointers will be at zero.

[underlined] Leak Test MK XIV. [/underlined]

With a piece of rubber tubing applie [sic] the suction untill [sic] the pointer reads 1,000 ft. seal of and the pointer must not drop below 950 ft, in less than one minute

[underlined D.I. MK XIV [/underlined]

C.G.V.D.S. set the B.P. of day and the pointers are allowed to indicate between +50 – 80. then neglecting the slight change return the pointers to zero Costal Comand [sic] and

[page break]

Fighter command usualy [sic] set there pointers to zero and bomber command set the high of aerodrome above sea level.

[underlined] The Rate Of Climb Indicator. [/underlined]

The principal of this instrument is that of of [sic] . pumptered [sic] type i.e. if blown up it will remain expanded and if no pressure is applied will remain deflated it has three function.

1. Used in conjunction with A.S.I. will help the pilot to prevent the A/C from getting into the [underlined ] “stalling angle” [/underlined] [deleted] (to) [/deleted]

2. Gives an indicating of level flight.

3 Used with the altimeter A.S.I. and [unreadable word] beam Will helf [sic] the pilot to land an A/C under conditions of darkness or poor visiablety [sic]

To installed top right in the B.F.,P, by two, to B.A. nuts and bolts there is a nipple at the rear which is connected to the static side of the pressure head or in moderate form of A/C to the static vent at the bottom right hand side of the indicator is a small screw head which when turned moves the pointer and provides an zero adjustment.

[page break]

[underlined] Leak Test. [/underlined]

Using a U tube of water and a T. piece applie [sic] a pressure equal to 114” of water, seal of and the level must not drop more than one inch in less than ten seconds.

[underlined] Daily Inspection. [/underlined]

C.G.V.D + S. and set pointer to zero.

[underlined] 30 br 30*br. [/underlined]

Same as D.I. only a plus check calibrating

[underlined] Leak Inter. [/underlined]

[annotated drawing]

[underlined] Air Speed Indicator [/underlined]

This instrument indicates the speed of the A/C relative to the air, but not rel [missing text] the ground. It is a differential [missing text]

[page break]

gauge and measures the difference in pressure between still and moving air. The dail [sic] is calibrated in miles pr. hr or knots Two nippes [sic] at the rear of the moulded case are marked P. and S. These two nipples are connected by means of 5/16 in O.D. alum, tubing and low pressure unions to there respective tubes on the pressure head.

In flying boats, etc, the tubing is of cappw [sic], and the low pressure unions are of brass owing to the corrosive effect of salt water on alum,

It is essential for accurate reading that all unions should be tight. When A/C has folded wings, a flexiable [sic] metal – braided tubing is fitted near the hinge. The instruments are fitted in the pilot’s navigators and bomb – aimers cockpit.

[underlined] The pressure Head [/underlined]

Consists of a static and a pressure tube mounted parallel x. to close to each other. It is fitted on the A/C out of the slipstream of the air screw and pointed forward, The pressure is open at the front, and which the static is closed and pierced radically with small holes, at right angles to the airflow.

trap is fitted to the pressure [deleted] and [/deleted]

[page break]

[underlined] Boost System. [/underlined]

It will indicate to the pilot the pressure in [deleted] which [/deleted] the induction system of a super charged [inserted] aero [/inserted] engine selective to an normal atmospheric pressure at sea level nipple connection soldered on, Set pointer to pressure of day and lubler [sic] line to maximum

Choke fitted in union at back very tiny hole.

Should read barometric pressure of day. Filter fitted in hole behind the choke centre one to boost gauge and the other one to indicate a system Leak test.

If the gauge goes up to 4lbs apply a pressure 4lb pr sq ins” and the pointer should not come back 1/2”lb pr sq in in one min.

[underlined] The Gyproscope. [sic] [/underlined]

[underlined] Spaced Gyproscope. [sic] [/underlined]

A perfectly balanced gyro which will maintain it position in space

[underlined] Earth Gyroscope. [/ underlined]

A specially unbalanced gyroscope which maintain itself so that there is no negative between the gyro and the earth

[page break]

[annotated drawing of a Suction System]

[page break]

are interchangeable according to the direction of rotating of the engine, Flexiable [sic] hose should be used in connecting the unions to the rest of system

[underlined] Pisgo relief Valve. [/underlined]

It is fitted close to the pisgo pump and is the means of adjusting the suction, To increase the suction the adjivity [sic] screw should be turned in anti-clockwise direction, A filter is fitted to prevent dust entering he system,

[underlined] D.I. – [/underlined]

Check for general security

[underlined] Front Minor Inspection – [/underlined]

Remove clam and replace filter

[underlined] Sperry Suction Relief Valve. [/underlined]

It is fitted on the mounting unit and enables a fine adjustment to be obtained for the suction in the system,

To increase the suction remove the cap and turn the adjusting screw clockwise tighten the lock nut and replace cap.

[underlined] D.I. x F.M.I. [/underlined] as Peago pump.

[page break]

[underlined] Check Valve. [/underlined]

This is fitted [deleted] (etc) [/deleted] in the suction pipe line to protect the gyro units against back pressure of oily air should the gyro pump reverse it direction of rotation The arrow on the casing should all ways point towards the pesgo pump.

[underlined] The Air Relay Valve. [/underlined]

To transmit the control from the gyro to the balanced oil valve

[underlined] Description [/underlined]

It consists of two aloid [sic] castings bolted together, having a reindeer skin dio, between them, The dia, is strengthened by two metal disc’s having a spindle attached to the centre which connects to the balanced Oil valve,

Air is drawn in through a filter at each side then passo to the fiche off it in the unit, [deleted] Mn [/deleted] Normaly [sic] the small parts are half covered and the pressure in either side of the A.R.V. equals, If the A/C is disturbed the movement of the pick off over the knife edge casues

[page break]

the pressure to be unbalanced in the airrealy,

the dia, is deflected therefore causing a movement of the B.Q.V. piston allowing oil to pass to one side of the servo motor this applying A/C controls to bring the A/C back to its normal flying position

[underlined] Test. [/underlined]

Hold the A.R.V. in a horizontal position with the spindle uper [sic] most with the thumb lightly point to spindle up it should fall back smoothly to its original position.

Reflect this test [inserted] with [/inserted] [deleted] it [/deleted] the spindle in a downwards position

[drawing of a Dain Manifold]

[page break]

[annotated drawing of Oil Layout]

[page break]

[underlined] Sump. [/underlined] (oil system)

To Supplie [sic] the system with oil it also collests [sic] drainage oil from the system

Description.: –

It is anloid [sic] container having a number of unions a filter plug, a drain plug, and an inspection window. It must be fitted below the level of the mounting unit in order to provide gravity drainage it should be maintained 3/4 full on a D.I.

In some A/C a sump is fitted which supplies oil for the operation of the Hydrowlic [sic] system therefore the sperry system maybe connected to the same sump.

[underlined] Oil Pump. [/underlined]

To provide a rate of flow of oil through the system

[underlined] Description. [/underlined]

It consists of anloid [sic] casing casing [sic] and two gear wheels one of the gran wheels being driving of the crank shaft of the engine. The pump can only be fitted to the type of engine it is made to suit.

Care must be taken therefore to ensure

[page break]

that the rotating of the pump considers with the direction of rotating of the engine to this effect there is an arrow on the back of the casing. The inlet is clearly labelled [underlined] IN.L.E.T. [/underlined] and the pipe line from the sump must be connected at that point

[underlined] Oil Pressure Relugar [sic][/ underlined]

To regulate the pressure of the system to + x – 10 lbs of the pressure layed down for that particular type of A/C. To increase the pressure the screw should be turned in a clockwise direction

[underlined] D.I. [/underlined] Check V.D.S

[underlined] F.M.I. [/underlined] Same as D.I. only check 2 way cock.

Purpose – This is fitted between the oil filter and mounting unit and provides a means of by passing the oil back to the sump when carring [sic] out any repair or inspection on the mounting unit side of the system. It also enables the pilot to pass the oil back to the sump should leakage occur during flight

[page break]

[underlined] Mounting Unit. [/underlined]

This consists of a frame supported by 4 lord [sic] AUMS in the cockpit in position where the B.F.P. is usually situated. The two units slide into this frame and are held by to bolts attached to the mounting unit are the three air relay valves 3B.D.V.S. electrical connections main suction drain and pressure manifold and on end the sperry suction relief valve is fitted

All connection to the mounting unit are of flexible hose.

[underlined] Testing Over Ride valve. [/underlined]

A. Connect to direct oil pressure gauges to the 2( working manifold block.

B. Start up A/C engine and put engaging lever [underlined] on [/underlined]

C. Applie [sic] manual controll [sic] till one gauge reads 25lbs pr sq in above normal working pressure the valve the connected should then blow off

[deleted] Testing for air in zero meter [/deleted]

[deleted] The engines must be of an of engaging lever or [/deleted]

1. Reflect moving control in opposite direction adjust by grub screw if necessary

[underlined] testing for Air in the Servo Motor. [/underlined]

The engines must be off

on engaging lever on applie [sic] manuals pressure

[page break]

[underlined] Daily Inspection on Sperry. [/underlined]

1. Check oil level it should be 3/4 full

2. “ for air in the servo motor.

3. “ the vacuum it should be 3ins HG at a thousand revs and 5ins at full maximum n [missing text]

4. “ the oil pressure it should be within plus or minus 10lbs in pressure.

5 On cage [deleted] the [/deleted] climbing unit and if A/C is not level the gyro should slowly move towards an indicating of the A/C attitude

6. Set and uncage D.C. test compass card for freedom and bare caged or locked

7 “ the speed control valves to the figure layed [sic] down.

8 Using controll [sic] knob set the following up idices [sic] to the gyro indicating

9 Set the levell [sic] control to off

10 “ the engaging lever to on and with engi [missing text] on test operation by moving the control knobs and noting the controls move in the correction, They should move at approx., equal spedd [missing text] either way and should not unslate [sic] or Lunt and come to rest immediately

11 Disengage gyro pilot.

[page break]

[underlined] Drain Trap – [/underlined]

provides a means of returning drainage oil to the system consists of a copper float, a needle valve and has three connections. The lower connect is connected to the sump pump pipe line the top connection are connected to the drip tray or the drain manifold the remaining top connection ascs as a vent to atmosphere. The drain trap should be fitted below the level of the drain manifold but not more than 5ft below the level od the pump

to A/C controls should indure [sic] move it denotes air in servo motor.

[underlined] Removal of Air from Servo Motor. [underlined]

Engine switched on

Engage lever switched off. hold A/C controll [sic] to fullest extend in each direction for 30 secs this should remove air from servo motor (MB) setet [sic] for air in servo motor

[page break]

[underlined] Filters (13 in all) [/underlined]

Air Relay 6

Bank and Climb 2

directional Gyro 1.

Sperry Suction RV 1

Pesgo suction RV 1

Oil Sump 1

Main oil filter 1

[underlined] MK. IV Auto Controls. [/underlined] (108lbs)

[underlined] Compressor: – [/underlined]

To supply air to the system 60lbs pr. sq. in. to spin the motors of the gyros and gives the operating power for the servo motor.

[underlined] Description. [/underlined]

It has three connections the oil inlet air inlet and oil and air outlet.

The oil inlet & air inlet house the filter and care should be taken to ensure after cleaning that new washers are placed either side of the lamp union before replacing. An arrow on front plate indicates direction of rotating The connections two and from the compressor are of avro of leaves, the

[page break]

[annotated drawing of MKIV Auto Controls. Pipe diagram.]

[page break]

front cover plate contains packing and mut [sic] the packing consisting of asbestos yarn treated with tallow and graphite the shafts deliberately weakened about one inch along the shaft and is Amoar [sic] as the servo much this ensures should a compressor sequen [sic]occur the shton [sic] shaft will break lef [sic] damage can be done to the engin [sic] or cranft [sic] shaft.

[underlined] Daily Inspection. [/underlined]

Test for general and leaks.

[underlined] First Minor Inspection. [/underlined]

Remove the filters wash in M.T. petrol replace making [deleted] shu [/deleted] sure that the washers have been annealed.

[underlined] Oil Resevar [sic] [/underlined]

It is used to store oil to lubri [sic] and seal the compressor. It also partiu [sic] separates the oil form the air coming form the compressor threaded into the bottom in a spring loaded barrel filter with an outlet leading of to the Auto valve and oil cooler,

[page break]

Fibre washers are used where required to make connections air tight.

[underlined] Daily Inspection. [/underlined]

M.K. IV Type

Fill to the level of the filter up with anti – freezing oil check for general security and leaks.

[underlined] M.K. III Type. [/underlined]

Set hands on gauge vertical unscrew filter cap fill in A/F oil until the oil level in the glass reachs [sic] the [unreadable word] ft, mk. replace the filter cap and locked the hands in a horizontal position

[underlined] First Minor Inspection. [/underlined]

By means of the drainage plug at the bottom drain of all dirty oil remove the filter wash in MT and replace fill up with A/F oil as on a DI.

[underlined] Automatic Valve. [/underlined]

This is a one way valve and is fitted [inserted] near [/inserted] to either [deleted] near [/deleted] compressor or

[page break]

the oil reservor [sic] which is lowest in the system, It is designed to keep the pipe line full of oil, but without fback [sic] the compressor. It must always be fitted with the arrow pointing towards the compressor.

[underlined] Oil Cooler. [/underlined]

This is similar to a long comb and is fitted between the oil reservor [sic] out [missing text] x oil inlet on the compressor. It is fitted in the slipe [sic] stream to cool the oil to an reasonable temperature

[underlined] Daily Inspections [/underlined]

Check for general security and [missing text]

[underlined] Chemical Air Drier [sic]. [/underlined]

Is installed to observe any moist [missing text] in the air, and so prevent it from entering the system thus elimating [sic] freezing etc, It is fitted in the pipe line between the oil reservor [sic] a [missing text] test cock.. [deleted] The [/deleted]

[page break]

[underlined] Method of Charging [/underlined]

Remove iner [sic] container empty the contains and wash in petrol, he outer container must or should be washed with soap & water,

1) Fit a gauge disc

2 Fill to within [underlined] + [/underlined] ins, within the top wil [sic] silin [sic] gel

3) Fit the other gauge disc, 4) place lair [sic] of new cotton wool on top of gauge disc making sure it is tightly packed

5) Replace the cover on the container & screw into position on the bracket attached on the A/C making sure the rubber washers are in good order

[underlined] MK IV. Type. [/underlined]

Will last for three engine hrs.

MK. V = Will last for ten hrs.

[underlined] Test lock M.K. IV [/underlined]

It has two position flying and test.

In the flying position air passes from the C.A.D. to the M.C.G. In the test position pressure is cut of from the compressor and a connection make to the portable compressor so enabling the system to be

[page break]

tested on the ground, The test coc [missing text] is not bolted to the A/C but in the ppe line by two screw air tight unions

When the test cock is in flying position it is locked by an [sic] small spring ingag [missing text] on a pin attached to the handle

[underlined] Test Cock MK. IV A [/underlined]

Charging from flying to test [missing text] takes place automaticly [sic] by means of pressu [missing text] operated on a plunger.

[underlined] Servicing VI. [/underlined]

Should a leak occur or a falte [missing text] washer wash in petrol, When remo [missing text] unsure that the rubber washer on the plunger is uper [sic] most

[underlined] The Test connection [/underlined]

Should be screwed on hand tig [missing text] and locked by means of the locking [missing text]

[underlined] Air Intake Throttle. [/underlined]

Purpose –

1. To maintain the pressure in the sy [missing text]

[page break]

at 60lb pr sq in. above atmospheric pressure

2. To act as an unreturn [sic] valve when the engine back fires it has three connections the telx [sic] one from the regen [sic] centre one to compressor and bottom one form main supply.

an arrow indicates the direction of flow of air to the compressor. There is a filter at the top this is called the breather. The two atmospheric vents are connected to the inside of the selfhome [sic] bellows to prevent compressing of air which would give errors in the output of the compressor

[underlined] Servicing. (DI) [/underlined]

Visual bfects [sic] security

Minor Inspection plus DI. only clean filter.

[underlined] Main Control Lock [/underlined]

Purpose – To provide a means by which the pilot can engage the Auto, controls after spinning up the gyro.

[underlined] Description [/underlined]

The casting has four connections and one vent to atmosphere. The barrel is so drilled that a passage of air from the inlet can travel

[page break]

[annotated drawings of Control lock]

[page break]

to any of the outlets as required.

The M.C.G. has three positions and the barrel is rotated by a handle into any [deleted] of [/deleted] one of three positions, they are out, spin, & in, In the out position the air go back to the compressor by the segon [sic] system. There is a restriction choke to ensure an emdiate [sic] held up of pressure When the compressor starts.

In the Spin position the air goes to the spin jets also to the steering controls. In the IN position air goes to the centrilyin [sic] and the main valves and also to the same positions as in spin

[underlined] Installation [/underlined]

The handle can be put in any one of 6 positions, and a deturn [sic] line on the barrel and one on the casting are to indicate the out position of the M.C.G when they are lined up.

The plate on top is reversiable [sic] and with the deturns [sic] lines up and the handle in the must conveint [sic] position for use the plate mustbe [sic]

[page break]

replaced with the word out against the hand installated [sic] in pilots cock pit

[underlined] Servicing (DI) [/underlined]

Test for freedom of movement and security and Care the handle in the out position

[underlined] The Steering Control. [/underlined]

Purpose: –

To enable obesever [sic] or bomb aimer to change the course of the A/C while under Auto, controls as desired for bombing runs etc, Fitted in the bomber – aimer compartment having three connections the centre one being the inlet the air coming form the M.C.C. in the spin and in position The other two connections are the outlets to the course change valve via, the turn regular [sic] the inlet connection has a filter which is make up of two gauge discs and cotton wool held in position by a circible [sic]

[underlined] Servicing (D.I) [/underlined]

Test for freedom and security ensure

[page break]

that the control fully springs back centre position

[underlined] First Minor Inspection [/underlined]

DI. plus clean filter

[underlined] Steering Lever. [/underlined]

It is fitted in the pilots cockpit and is to enable the plot to change the course of his A/C under automatic controls, ad is connected to the steering control by bourden [sic] cable

[underlined] Note 1 – [/underlined]

At the rear of the steering control there is a note of turn adjusts this is adjusted to the no, of degrees as layed [sic] down for the particular A/C in the A/C manual.

[underlined] Combined Air Pressure. Gauge [/underlined]

This gauge is used to indicate the pressure in the system also as an indicator to the f/aft trim if the A/C. It has three connection at rear A,B. up, and C. down, Connection A will be T. in the supply pipe line between the test cock and M.C.C. Connections B & C are

[page break]

[annotated drawing showing Diogramatic sketch showing A. course change.]

[page break]

connected to either side of the elevator S/M.

[underlined] 1/10/43. [/underlined]

[underlined] D.I. C.G.C.V.D.S. [/underlined] and with engines running the pointer on the right hand side of the dial should read 60lb pr. sq. in.

[underlined] Twin Regulator. [/underlined]

In very modern A/C it has been found that thy will not turn at the same rate as the outer jimble [sic] ring, The must is there for that the O,R, moving faster than the A/C. the centrelyir [sic] pin touches the cone and the jumlb [sic] system toples [sic], This happens when the outer ring has exceeded the turn [deleted] of the turn [/deleted] of the A/C G16 1/2 degrees.

[underlined] D.I. [/underlined]

Check for general security switch on and note that the electrical magnetic become engemging [sic]

[underlined] Note: – [/underlined] The turn regulator operated by two contacts in the R and E plate Stop the outer ring pressuring The contacts are broken when the pin on the out ring engages with the long contact this takes place when the outer ring has exceeded the A/C turn G 16 1/2 degrees.

[page break]

[underlined] Servo Motors. [/underlined]

The s/M consist of an out side casting with two pistons inside each redgity [sic] attached by a toatl [sic] rech [sic].. Movement of piston & rach [sic] rotate a pinion attached to a shaft on which is carried a pully or a chain sprocket, this sprocket is connected to the A/C controls,

A realise clutch is provided which enables the pully to rotate freely [deleted] with [/deleted] the clutches in the out position.

A second pully is hyd [sic] to the same shaft and operates the [underlined] follow up cable [/underlined] thus moving the follow up units in the back of the plates

[underlined] D.I. [/underlined] C. for general security make sure that the clutch tongue clearance s 50 thou, with the clutches in the out position. Engage the clutches and operate A/C controls manualy [sic] until the clutch tongue fits into the groove in the clutch plate.

[page break]

[underlined] 1/11/48. [/underlined]

[underlined] Centrelizer [sic] R.E. [/underlined]

Purpose: –

1. To lock the gimble system when the A/C is taking off and landing and with M.C.C. in the OUT and SPIN position.

2. Supply air to the main valves with the M.C.C. in the in position,

3. Exhaust the air from the S/M when the M.C.C. is in the out x [inserted] spin [/inserted] position [underlined] 3/10/48 [/underlined]

[underlined] Action [/underlined]

When pressure enters the inlet from the in position of the M.C.C. it passes into the front of the piston forcing the piston back against the tenstion [sic]of the spring, he cone is therefore moved away from the centrilyer [sic] pin the rubber washer attached to the piston seals of the parts from the S/Ms closing them from atmosphere.

[underlined] he Relay Valve. [/underlined]

The relay valve is fitted to prevent stihing [sic] the would relay passes the outer ring through the back torque being applied to the iner [sic] ring the result would be bad course keeping

[page break]

[annotated drawing showing Rudder Hnd. Elevator Plate]

[page break]

[underlined] 3/10/40. [/underlined] This is eliminated by attacting [sic] the fairy piston to the iner [sic] ring linkage and the relay valve relaying the movement to the main elevator valve.

[underlined] The Watts Weight. [/underlined]

Purpose.

It is fitted to counteract the efforts of centrifugal force on the act of the balanced mark of the jimble [sic] system It also acts in spectched [sic] stabilgidatign [sic] and aids the mans balanced weight to make the inter ring to confimed [sic] to the cariture [sic],

[underlined] Rudder And Elevator Writ. [/underlined]

It consists of two parts the frame which is billed to the port side if the A/C and a base which is carried on the frame and allowed to rotate, The base can be rotated by means of louden cable from the pitch attuide [sic] control. The jimble system is connected to the base by pivots top and bottom of outer ring and are of set 15o. The rotor spins at approx. 18 to 20 thousand rev, pr, ring and is forced round by a two that jy [sic] The jimble system is connected to the watts weight which tilts forward 15o ths given pitch stabilization it is locked by means of the centrilizer [sic] laying immediately above the watts weight – The rudder valve is a

[page break]

attached to the outer ring while the relay valve (elevator) is attached to the iner [sic] ring. To prs of turn regular contacts are mounted on the top of the outer ring, between which is the contact breaker attached to the outer ring.

[underlined] Position Of Filters. [/underlined]

[table showing R & E Plate, Sub & Main]

[page break]

[underlined] Filters on Componant [sic] [/underlined]

Compressor. 2.

Oil Reservor [sic]. 1.

Cleaned Air drier 1.

Air intake trottle [sic] 1.

Steering control 1,

[underlined] Datums [/underlined]

1 Datum on fixed and rotating part of the plate to indicate the position of the plate when the attitude it at zero,

2. A datum in either side of the base plate which should be in line with the f/aft axis of the A/C.

3. A datum on the pinion and base plate under the dust covers for the purpose for getting the valve control in these slides during installation.

4. Datum on valve casing and valve slide for the purpose of getting the valve casing central over the valve by fine adjustment of the louden cable ( 3 & 4 apply to the rudder & Edwalh [sic] (follow up system

5. A datum on the rack and pinion of the S/M indicating the centre of travell [sic]

6 A datum on the MCC. to indicate the mcc. in the out position

[page break]

[underlined] Fitting Of The Follow Up Cable [/underlined] (On Sperry)

Fit the follow-up pully onto the exell [sic] of the serrated disc taking care that the clutch pin engages and that the leaf in the spring fitts [sic] over the pin projecting from the mounting unit, The servo motor piston must be placed in an extrem [sic] position and the cable attached to the short end attach the cable to the piston by a shackle and pin pass the cable round free pullys [sic] and had it to the back of the mounting unit wind up the spring in the pully on the mounting unit to its fullest extent and release a quarter of the turn pass the cable case round the pully and through the hole provided Mark the position where the cable passes through the hole tie a knot on the cable at the point solder and cast of excess cable round installation may be checked by the movement and direct of the fallow of pully

[drawing showing elevator, aileron and rudder movement]

[page break]

Eileron [sic] Plate.

Pricessing [sic] Valve and torque motor

Purpose:

These are fitted to the ililion [sic] unit and cause the outer ring to fricen [sic] at the same speed as the A/o is turning.

Action.

Air is lead to the processing valve from the spin position of the M.C.C. the valve casing being attached to the base plate

and the piston attached to the outer ring any movement if the A/C in turn will cause the casing to move over the piston. This allows air to pass to one side of the torque motor piston movement of the torque motor piston therefore will cause a linkage to move applying torque to the iner [sic] ring. This torque applyed [sic] to the iner [sic] ring causes the outer ring to process at the same speed as the A/C.

Eilleron [sic] Centrelyer [sic]

Purpose: –

Similar to that of the centrelizer [sic] on the R & E plate it was of a [deleted] unreadable word] [/deleted] paissor [sic] type and the minor engage with a pair attached to the inner ring

Some wont be taken to replace the Elanh [sic] off cap after completing your D.I. Louless [sic] to do

[page break]

would automatically make the unit w.s. The inlet filter on the centrelizer [sic] is situated on the supply connection outside the unit the outlet is situated ar [sic] left of the unit inside

The Gravity Weight

Purpose.

To counter act the effects of f/aft osileration [sic] and to act as an extra gravity control.

Daily Inspection MK IV.

R. and E. Unit.

Remove cover, decentrilize [sic], test motor for freedom, and outer ring for end play (100s ins). Examine all flexible hose or rubber piping, test all valves, pistons, and slide, and oil all moving parts with one drop of A/F. Test security of weights examine all louden cables ensuring they do not foul the plate when it is rotated. Recentrelize [sic], remove the surface oil from cover examine corkwasher for damage and replace

Aileron Plate

As above, but note that the centrelize [sic] cap had to be removed to allow the decentrelizing [sic] key to operate therefore cap

[page break]

[annotated drawing showing MK IV Cable Layout]

[page break]

must be replaced.

Components.

Air Intake throttle. V.D/S.

Compressor. V.D.S. also security of pipes and examine for leaks,

Alternative valve and oil cooler V.D & S.

Chemical Air drier V.D. & S. recharge if necessary.

MK. IV Int lock V,D.S. & lock in flying position

MK V “ “ “ “ “

Main Control lock. test freedom of movement and Care in out position

Steering Lever. test freedom of movement and leave control

Pick Altittude [sic] control “ “ “ “ “ “

Steering central “ “ “ “ “ “ “

Combined Air pressure gauge V.D.S.

Towen [sic] Regulator test functioning and put one drop of A/F oil in the piston

Clutch. Lever. V.D.S. Clutch the (.005) clearance and leave clutches in.

Installation

Follow – up cables including fitting and stripping of S/M.

1. adjust the end plates of S/M to suit position in A/C

2. Remove 2BH nut and clutch tongue

“ spring loaded plunger.

[page break]

4 By means of S/M knob extractor remove clutch plate from spline shaft.

5. By using to to. BA bolts remove follow up pully and dowllplates [sic]

6. Adjust position of stop plate to avoid bends in cable

7 Set the S/M central G datums

8 Re [missing text] dowel plate and follow up pully so that the nipple is 180o away from the centre of the dowdenstop [sic]

9. Replace clutch on spin shaft using asembly [sic] tool

10. Grease and replace spring loaded plunger and refit clutch torque megism [sic]

11. With the S/M. central note also that datums under dust covers and valves clicks are in line proceed then to fit cable.

12. Tension cable G means of the adjusters until keeper joint dropps [sic] off.

13 Test for correct operation by movement of rudder Comand [sic] control column, note correct rotating of follow up pully and control surfaces

Steering Lever And Steering control cable.

1. Set datum on steer lever fully and datum on base.

2 Set datum “ “ co “ ntrol “ “ “

casting

[missing text] ust louden stats on stume [missing text] troll and lec [missing text]

[page break]

Office in the slots opposite the adjustors

4. Ensure that when the s/lever is moved left A/C will also move to left.

Clutch Lever.

A single cable is lead from the clutch lever into centre riffle slott [sic] of the slider in the distriubtor [sic] two cables lead from this, one to another slider and dist [missing text] the other to the S/M so giving three cables to the S/M

With clutch in there should be slack in the cable and slider should be 2/3 down the distributor case, With clutch out clutch should be ober [sic] of the clutch plate G (005”), any adjustment to be on distributors on S/M.

Pitch Alititude [sic] controls.

1. Ensure P.A.C. is installed with datums on front cover and has aligned so that the oil hole it at the top

2. Remove front cover, and with P.A.C. reading zero locate an With 1/4” ripple in its slot.

3. Line up datum on rotatable platform with arrow lead on base plate and locate cable around plate with 3/4” riffle is it

4. Set for clockwise rotating of unit when P.A.C. is moved to climb

Characteristics of the cables.

1. P.A.C. along length of lone cable and 1/4” & 3/8” riffle, two adjustors and cable crossed when installed

2 Steering lever to [missing text] ing control cable short length of [missing text] cable 1/4” & 3/8” riffle [missing text]

[page break]

there are seven terminals which are No 1 to 7. and are also coloure [deleted] d [/deleted] coded, One main switch operates all systems together (Design system)

[underlined] Installation. [/underlined]

D.1 C.G.V.D,S,

Switch on main switch and see that the dails [sic] indicate the amount of fuel, & oil, etc.

[underlined] 30br. [/underlined]

Inspect wiring terminals fuses and general security

[underlined] 30 * br. [/underlined]

Same as above oaG [sic] check calibration of Transmitters and indicators.

[underlined] Telegon. Equipment [sic].[/underlined]

The equippment [sic] is installed only in American A/C and these Boston, Havoc. Hilmore, The instruments which employ this system are 10 in number and are.

1. Oil pressure. 2. Oil temperature

3. Fuel “ 4 Air intake temperature

[page break]

5 Nose Wheel.

6 Port “.

7 Stbd “

8 Flap (position indicator)

9 Manifold press or Coast Gauge.

10 Fuel contents.

The advantage of the system are many and include the following : –

1 Fany [sic] maintenance and testing

2 Space and weight saving.

3 Extreme accuracy.

4 Interargeability [sic] and easy replacement.

5 Wses [sic] breeze wiring.

[table showing instrument / Code No / Code Colour / connection at rear]

[page break]

[underlined] Pressure Gauges Transmitting – Type Fuel And Oil Pressure Gaug [missing text] [/underlined]

In this type of gauge the pressure being measured is not in direct contact with the gauge, but us admitted to a closed case containing a flexible capsule, the inside of which is connected to the instrument by means of a copper capillary tube. The capsule, capillary, and lounden tube are completely fitted with a special fuild [sic] usually alcholal [sic] which acts as the transmitting medium. The system prevents loss of fuel and oil pressure which might be caused throught [sic] a faulty instrument.

[underlined] Daily Inspections. [/underlined] Clean glass visual defects and security.

[underlined] 30 br Inspection [/underlined] Int. functioning on ground test

[underlined] 30 * “ “ [/underlined] Examine capillary for highs and dents and security.

[underlined] Choke For “HYDR,” System [/underlined]

Purpose – To protect the gauge from flow.

[underlined] Installation. [/underlined]

1) Flush the pipe line to the choke (Petrol 50. [missing text]

2) Connect inlet to pipe line with [missing text]

[page break]

[missing text] ointing to the [deleted] (dail) [/deleted] gauge, leave half turn loose.

3) Leave two parts of the choke half turn loc and connection to gauge half turn loose.

4) Turn on oil and ensure it leaks freely from connections especially instrument one.

5) Tighten connection

[underlined] Note. [/underlined]

Dont [sic] attempt to alter choke jet if removed to clean filter proceed as if installing a fresh choke.

Three types of unions on instruments.

1) Nipple adapton [sic] union

2) Soft solder [deleted] ing [/deleted] ed spherical nipple union F.P.G. direct type

3) Spigot union.

[underlined] Transmitting Oir [sic] of Fuel Pressure Gauge. [/underlined]

[underlined] Installation. [/underlined]

Remove banjo union and capillary by unwinding off the drum not drawing off [missing text] ielly. If the instrument is to be [missing text] unted in the front of the panel, [missing text] the banjo union and capillary

[page break]

through the hole in the dashboard then secure the indicator. If indicator is to be fitted behind [missing text] panel the union and capillary will not have to be pass through. The union and capillary will have to be passed along the route to be taken, the capillary being cleated at frequent intervals (approx., every ft.) with metal clips lined with some resilient material. Finally ensure that the copper washers are in position when fitting the union, and that the capillary is looped with a minimum radius of 5/8 in any spare capillary must not be cut, but is to be coiled on the bulkhead in approx. 6” dia. coils cleated in at least three places.

[page break]

[annotated drawing showing Transmitting Oil or Fuel Pressure Gauge.]

[page break]

[annotated drawing showing Fuel Pressure Warning Lamp.]

[underlined] Purpose. [/underlined]

To give warning if fuel pressure falls below correct value.

[underlined] Consists. [/underlined]

1. Pressure Wnit [sic]

2. Resistence [sic]

3. Warning Lamp.

[underlined] Installation. [/underlined]

Pressure unit is secured to engine

[page break]

[missing text] ollow bolt after it has been adjusted [missing text] arning lamp is fitted on instrument panel, resistence [sic] where convenient in the circuit.

[underlined] Air Temperature Thermometer. (Strut Type) [/underlined]

The principle of operation is he expansion and contraction of alcohol, dyed red or black in a glass tube, The tube is triangles in shape, so as to maginify [sic] the column and make it easily visiable [sic] in a 14 degree arc when seen from a distance. A sun shield is fitted over the bulb it protect it from direct rays of the sun, the range of the therm, is from – 40o to and 60o (MK V.B.) and -35o to and 55oC (MK2

The thermometer is strapped to the port outer interplane strut, out of the slipstream of the aircrew.

The boiling point of alcohol is 78oC

The freezing point of “ “ -130oC.

[underlined] Air Phychrometer. MKV. [/underlined]

The purpose of the instrument is to give an illustration of the amount of water vapour in the air, It consists of two alcohol – in – glass thermometers

[page break]

mounted side by side. The bulb of one thermometer is enclosed in a muslin bag which is connected by a wick to a reservore [sic] of distilled water, evaporation of the water is accompanied by loose [deleted] (up) [deleted] in heat, conquently [sic] the bulb of the wet thermometer is at a lower temperature than the dry bulb. The more humid the atmosphere the lens will be evaporation from the wet bulb and consquently [sic] the loose of heat will be less, The difference between the two readings, or “wet bulb depression will therefore also be less.

It is the difference between the two thermometer readings which gives the indication of the amount of water vapour in the air, and an inspection of the tables in A,P, 275 will show that the greater the difference between the readings the less the humidity and vice versa. it is most important that the dry bulb should meet the airstream first, The instrument must be placed with particular side [inserted] for [/inserted] [deleted] up [/deleted] ward and the side is so marked as the dry bulb is mounted on

[page break]

[missing text] he left of the assembly the instrument must be mounted on a starboard strut.

[underlined] Installation. [/underlined]

The instrument is designed to be strapped to the starboard interplane strut (outer) of the biplane, so that the dry bulb is forward care should be taken to ensure that the instrument is in the pilots line of vision.

[underlined] Maintenance [/underlined]

The instrument should be periodically cleaned and the muslin bag and the wick should be washed and rinsed in distilled water the straps need periodical attention

[drawing showing Direct Air reading Therm temp]

[page break]

[underlined] Purpose. [/underlined]

To show the air temperature, this type will replace cappillary [sic] and electic [sic] types on 4 engined [sic] aircraft.

[underlined] Installation. [/underlined]

The scale is fitted inside the aircraft where the observer or pilot can see it. The bulb prortudes [sic] 1 inch through the aircraft skin and is protected by a metal sun shield.

[underlined] Maintenance. [/underlined]

See that the scale is elegible [sic] and the file mark on the glass is opposite zero on the scale,

[underlined] Oil And Air Temperature Thermometers [/underlined]

Both these instruments are required to indicate temperatures less than +40oC consequently the vapour pressure type would not suitable, The mercury is steel type, which is really an adaption of the mercury in glass type is there for used, The instrument may be considered is consisty [sic] of 3 parts –.

1). The bulb in both case in of

[page break]

[drawing showing Temperature Thermometer]

[page break]

and is completely filled with mercury. The bulb of the air temperature thermometer is long and copper coated and enclosed is a [deleted] copper [/deleted] metal shield to protect it from the direct rays of the sun, The bulb of he Oil temp, therm, is similar to that of the Radiator Therm, has a rounded end.

2).

The capillary (.006 in bore) is of steel and covered with a protective braiding. It is completely filled with mercury when the capillary of the air temp therm, exceeds 20ft in length, temperature compensating links are fitted at intervals of 20ft..

These links consist of an enlarged portion of capillary containing an inner steel rock.

3/.

The indicator is of the lundon tube type the tube being completely filled with mercury. The lourdon tube takes the form of a double spiral spring to the inter coil of which a bi metal piral is fitted for temperature compensation

[underlined] Installation. [/underlined]

To similar to that of Radiator thermom [missing text]

[page break]

[underlined] Maintenance [/underlined]

D.I. – Clean glass and inspect for visual defects the indicator should be reading the temp, of t [missing text] time of the inspection

[underlined] 30. br inspection. [/underlined] Int oil temperature for correct func [missing text] on ground test.

[underlined] 30* br “ [/underlined] Examine capillary for kinks and dents security.

[annotated drawing showing air temperature]

[page break]

[underlined] Reads the temperature of the days. [/underlined]

[chart for height and air speed]

[underlined] Compression Error Card. [/underlined]

Conection [sic] to subtracted from reading.

Air Temperature MK.III.

Similar to MK.II. expect that the bulb is fitted in a case from which it cannot be removed. The case is mounted flush with the mainplane and insulated from it is to fibre washers. No Error Card is required. D.I. and maintenance as for MK.II.

[drawing]

[underlined] Radiator Thermometer/ [/underlined]

The instrument has been design

[page break]

to indicate to the pilot the temperature of the liquid in the cooling system of the engine. The principal of the operation is that the vapour pressure of ethyl ether is a definite figure for given temperature. A vapour pressure is not o until a temperature of [underlined] 35oC. [/underlined] is reached The instrument maybe considered to consist of three parts. –

1, The bulb of brass and copper. (flat ant end) is two thirds full of liquid, th the remainer [sic] of the spare being vapour the tube reaches half way down the

2.

The capillary of I.M/M. bore also of copper completely filled with liquid.

3.

The indicator is of the lourdon pressure [missing text] type, the tube being completely filled w [missing text] liquid, the bezel is coloured blac [missing text] to indicate water, On some types there red markings on the scale to warn the [underlined] pilot of reducing [/underlined] B.P. at height.

[underlined] Maintenance [/underlined] D.I. C.G.V.D,S.

[page break]

[underlined] 30 br. inspection. [/underlined] test functioning on ground test.

[underlined] 30* “ “ [/underlined] Examine capillary for kinks and dents.

[underlined] Thermometer Calibrator. [/underlined]

The master thermometer and bulb af. instrument under test are clipped together and placed in the can, hot water is then poured in, The water must be hot enough to allow a first reading of 90o to be taken, then as the water cools, the reading of the master thermometer and instrument dail [sic] should be checked at 80oC and 70oC.

[underlined] E.S.I (Mech) [/underlined]

[annotated drawing]

[page break]

[underlined] Flexible Drive. [/underlined]

Brass casing

Drive held in place by split washers at each end, one must be taken off to remove [missing text] drive, the casing can be slightly lengthene [missing text] or shortened by screwing it.

[underlined] Steel casing. [/underlined]

Drive has collar at one end and cas [missing text] can not be adjusted

[underlined] Mechanical. Engine Speed. Indicator. (ESI) [/underlined]

These instruments have been dis [missing tet] to indicate to the pilot the rate o [missing text] revolution of the crank shaft of an a [missing text] engine, There are at presant [sic] three employed in the service, one which mechanical and two other electrical.

[underlined] Mechanical. Type. [/underlined]

The instrument operates on the pres [missing text] of the centrifugal govenor [sic], the mechanism is enclosed in a metal case which h [missing text] circular dail [sic], The instrument is usualy [sic] driven at engine speed by a flnabl [sic] which runs at a quarter engine speed

[page break]

order to reduce wear, To make this pou [missing text] gear boxes of various types are employed. P [missing text] drive consists of several layers of stub were wound in opposite directions to provide flexibility and strength, This runs in a flexiable [sic] brass outer casing, To the ends of the drive are soldered squared connectors, The drives are retained in there casing by means of slip washers, and they should have 1/8 to 1/4 fly. Holes are drilled in the engine end of the flex drive to prevent oil pressure forcing oil along the drive casing to the instrument.

[underlined] Installation. [/underlined]

Flexiable [sic] drives should be supported at intervals along there length and care should be taken to see that there are no sharp bends, A carelessly fitted drive may cause the indicate pointer to fluctuate.

[underlined] Maintenance – [/underlined]

[underlined] DI [/underlined] – Gear boxes and drives should be greased periodically with anti – freezing grease.

[page break]

[underlined] Air – Craft. Clocks. [/underlined]

[underlined] lock MK.I. [/underlined]